08

Portfolio

Officina 3

Intro

Reducing and standardising lead times in a highly variable environment through the introduction of a prioritisation system

Industry

Production and processing of accessories for high fashion

Headquarters

Padua, Italy

For Officina 3 – a company specialising in the production and processing of patches and labels for high fashion, apparel, footwear and leather goods – time is a crucial factor.

The absence of a structured organisation was slowing down processes – particularly in sampling and prototyping, where requests are high variable – making it difficult to meet deadlines and guarantee reliable delivery times.

To improve operational efficiency, we began a reorganisation process with the company based on lean methodologies. A thorough analysis identified key inefficiencies, including unclear priority management, which was causing delays in the production flow.

This led to the implementation of a pull system, enabling work to be carried out based solely on actual demand, thereby avoiding wasted time and resources. At the same time, the most critical operational stages were standardised – also thanks to the introduction of a prioritisation system – to ensure higher quality and reduce unforeseen issues. Officina 3 has successfully reduced and stabilised lead times in sampling and prototyping, improving request management and on-time delivery. The company can now offer high-fashion brands a more reliable and efficient service, strengthening its role as a strategic partner in an industry where speed and precision are essential.

Performance Achieved

0

0

Throughput time (from production launch to shipment)

Filippo Fiorin

General Management: Purchasing, Subcontractors and Logistics - Officina 3

Giacomo Fiorin

General Management: Commercial, Development and Production - Officina 3

Martina Fior

Production Manager - Officina 3

Stefano Cesarotto

Production Scheduling - Officina 3

Alessio Accardo

Sample Manager - Officina 3

Do you want to improve your company's performance?

Company

history

2001

Officina 3 was founded in 2001 as an Italian company specialising in the production and processing of accessories for the fashion industry, including clothing, footwear, and leather goods.

Today

Founded nearly two decades ago, the company now offers a range of products including patches, labels, ribbons, accessories, and panels for bags, accessories, and shoe uppers. All products are designed, developed, and manufactured entirely in Italy, enabling full control over every stage of the production process, from prototyping to final production.

Employees (2023)

0Turnover (2023)

0EBITDA (2023)

0

The challenge of Officina 3

Officina 3 faced the challenge of managing complex demand – characterised by a broad product mix and irregular volumes – within a multi-step production process marked by high variability. The goal was to reduce lead times to respond more swiftly to market demands.

The starting point

The transformation of the first macro-process: Delivery

2020

– start of collaboration

with auxiell

End

With Officina 3, we initially embarked on a project focused on the Delivery macro-process, which includes production, supply chain, and order management.

After optimising the Delivery processes, we undertook a project on the Development macro-process, focusing on the creation of new products and modifications to existing ones.

After improving the efficiency of the Delivery and Development processes, we undertook a project on the Deployment macro-process, which involves translating strategies into coordinated activities.

SCAN

Lean Gap Analysis® in Delivery

Given the nature of the fashion industry –where products have a short life cycle and are closely tied to current seasons and collections – speed is a critical success factor. Meeting specified lead times and ensuring the production of required volumes can make the difference in securing orders from major brands in the sector.

To assess the current state of operations, the auxiell-Officina 3 team conducted a Lean Gap Analysis® of the production process, focusing on the analysis and redesign of the various processing stages, including cutting, laser cutting, engraving (including high-precision and high-frequency engraving), flat/continuous engraving, screen printing, bonding, die cutting, calendering, lamination, embroidery, injection moulding, and micro injection moulding.

Lean Gap Analysis®

An essential phase for measuring and analysing current processes and identifying the gaps between the present and desired states.

During this phase, a 'snapshot' of the current state of processes is taken, focusing on quantifying waste, identifying potential problems and opportunities for improvement, and timing all steps.

Gaining a clear understanding of process performance is crucial for determining the most effective countermeasures to eliminate the root cause of the issue, as well as for planning future actions and determining which KPIs to monitor to improve efficiency.

The gaps that emerged

01

Delivery delays or partial deliveries of finished products

High production variability led to uncertain production times, which sometimes resulted in delivery delays, renegotiations of delivery dates with customers, and partial shipments.

02

High inventory and WIP levels

The long throughput time – from order to shipment of the finished product – led the customer to request continuous changes, resulting in production rescheduling. ‘Urgencies’ generated by planning changes ‘overtook’ work-in-process orders. Furthermore, there were frequent transfers between departments, as well as well as delays caused by a push-based production system, where material moved forward from upstream rather than being pulled in by the downstream stage.

03

Incorrect or incomplete production process information

The information required for the correct execution of operations to produce the finished product was not always accurate or complete. This increased the risk of errors, as it left it too much operational discretion to the department head and/or operator.

PLAN

Lean RoadMap® in Delivery

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN.

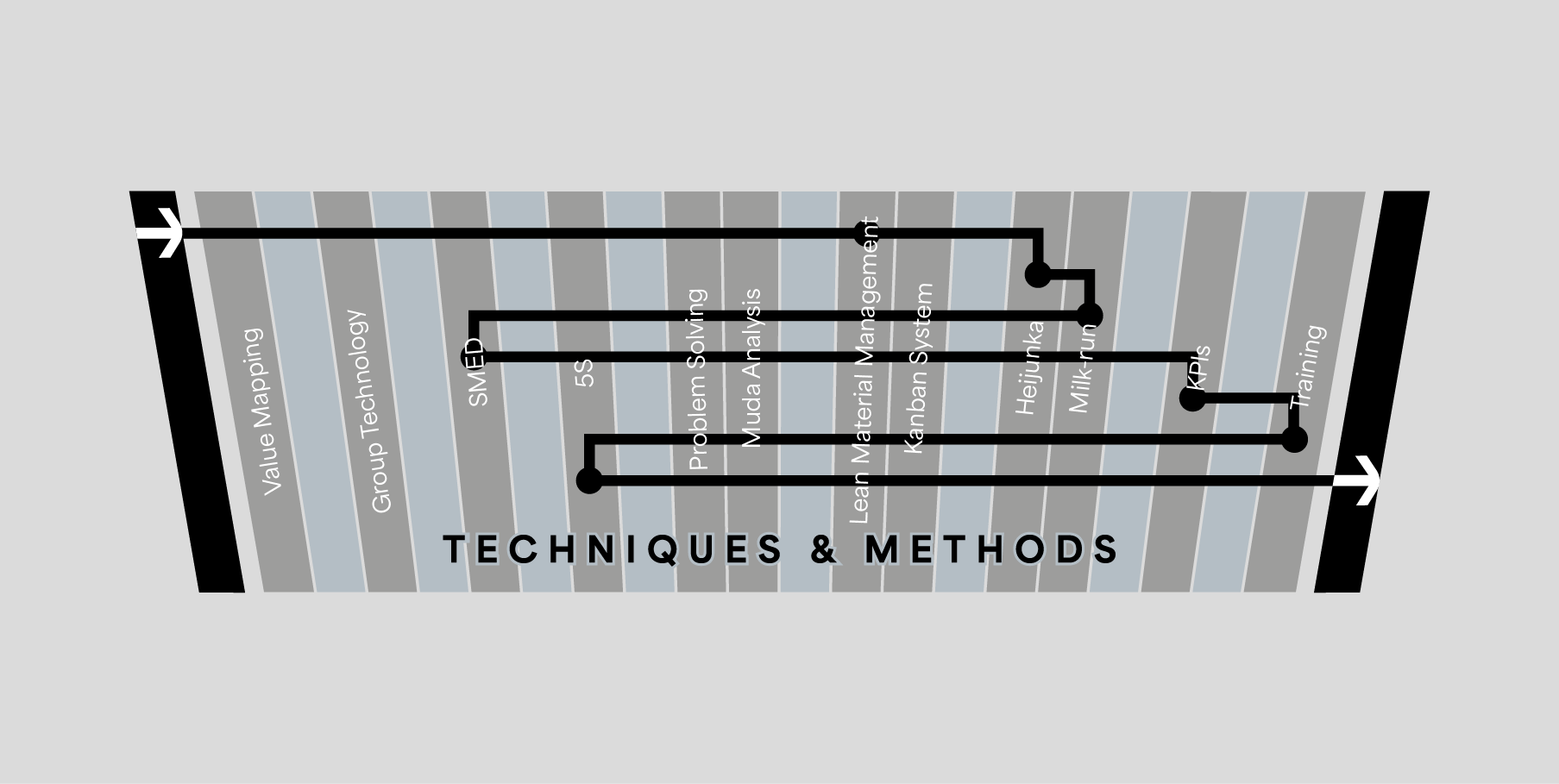

Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Officina 3 team.

The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective.

Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it.

The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

The path forward

01

Introduction of a prioritisation system

To reduce throughput times in a production process with high variability in product mix and volume, it is essential to connect the various stages using a pull system and to define prioritisation criteria – based on the available capacity of each stage – for operations at each work centre.

02

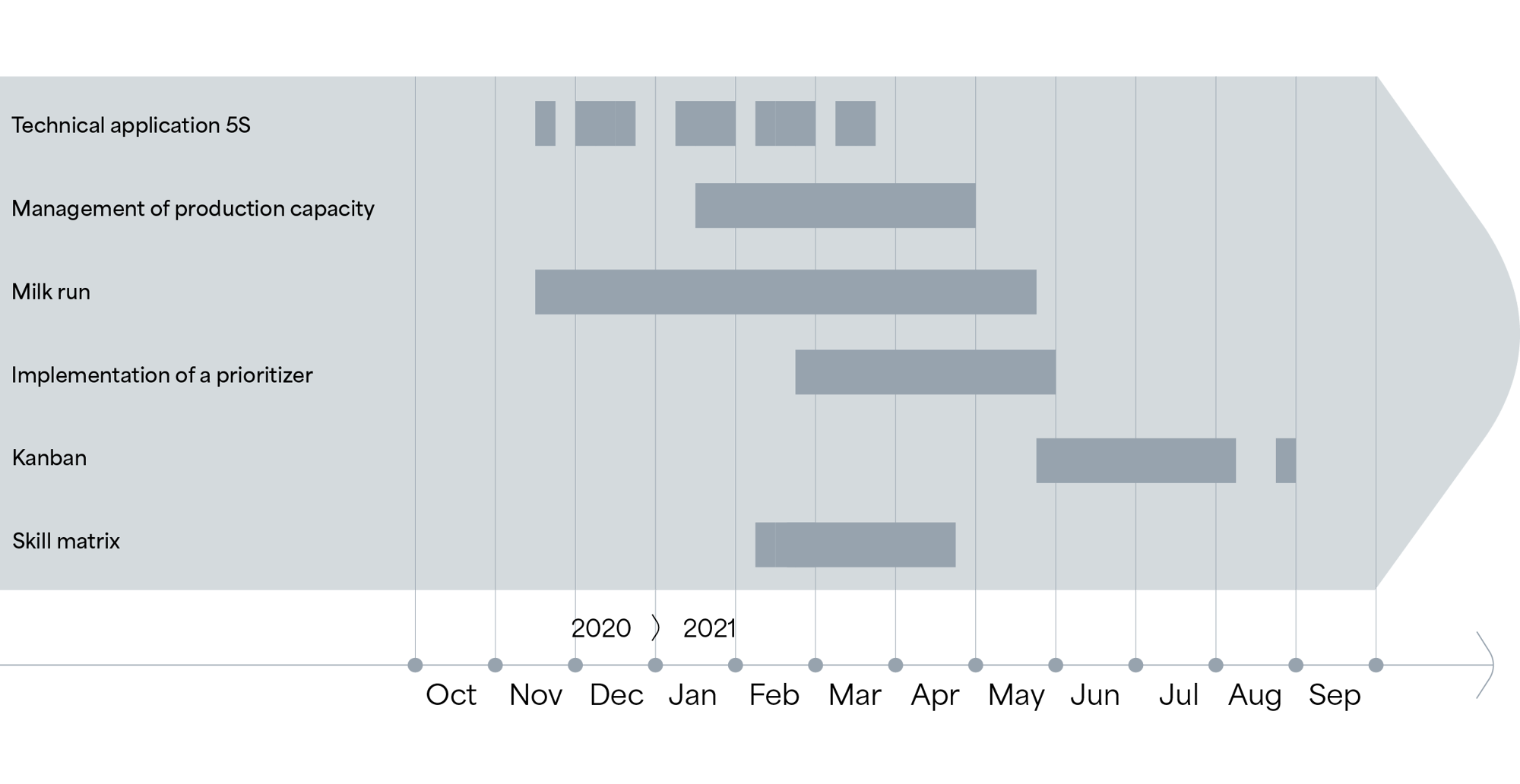

Implementation of a milk run

To reduce and stabilise lead times from both raw material suppliers (measured from order placement to goods arrival) and subcontractors (measured from dispatch of semi-finished products to their return post-processing. An additional benefit of the milk run system is the reduction of exceptional and urgent transport requirements.

03

Application of the 5S method

To encourage team involvement, training, and flexibility, and to foster a culture of order across both production and office environments.

04

Production capacity management

To better manage production shifts and assign tasks appropriately to operators, a monitoring system with peak detection was introduced.

05

Development of a skills matrix

To make the team multifunctional and direct training to the most workload-intensive phases. It also supports effective task allocation based on each team member’s knowledge and skill set.

06

Raw material kanban

To monitor stock levels of fast-moving raw materials while avoiding urgent replenishments and stockouts.

Expected benefits

Reduced lead time from order to shipment

Adaptation of market response models

Increased punctuality on deliveries

Reducing the transportation of materials between stages

New plant layout design with a view to process efficiency

DO

Delivery Overall Transformation

Which lean activities and techniques enabled us to achieve our goal?

Implementation of a prioritisation system

Using a whiteboard and tags, a bespoke tool was developed to regulate and monitor material flow between centres within a pull system. Specifically, to implement such a tool, the first step was mapping the work centres and identifying their characteristics (e.g. proximity or similarity in processes). Secondly, each centre was assigned a specific number of kanban tags, representing its production capacity. A whiteboard was then set up with the work centres listed in rows and time slots (by hour and week) in columns. Kanban tags are then placed at the relevant intersections. The board – referred to as the prioritiser – indicates which work centre has the most available capacity at any given time and should therefore be prioritised. The prioritiser visually displays the free capacity of the work centres.

Milk run

A ‘flexible’ milk run system was implemented for collecting materials from suppliers and subcontractors. It includes both fixed, scheduled stops and ad hoc stops triggered by production needs.

Application of the 5S method

Seven workshops were held to implement the 5S methodology, incorporating both theoretical training and practical application at specific workstations in both production and office areas. These sessions enabled the team to establish and maintain clean and orderly environments and to become autonomous in applying the method themselves. Every member of the Officina 3 team was involved and embraced the initiative enthusiastically. The 5S-based workstation redesigns received positive feedback from visiting customers and inspired the extension of the activity to subcontractors companies.

Production capacity management

Queue management via the prioritiser enabled stabilisation of lead times across the various stages, allowing prediction of the daily workload for each centre. This made it possible to intervene when workloads exceeded maximum thresholds, resulting in a smoother, uninterrupted production flow.

Skills matrix

Each team member’s level of knowledge and competence for each processing task was mapped. This data, combined with the production requirements of the various work centres, enabled the definition of a target level of multi-skilling. Training delivered by department heads to operators was then aligned with these targets and focused on critical competences. Finally, a process was introduced to periodically measure team members’ multi-skilling levels, in order to track progress against the established targets.

Raw material kanban

For fast-moving raw material codes, the optimal stock quantity was calculated based on forecast consumption and procurement lead time. A kanban tag was attached to each unit, which triggers the material replenishment process once the stock is depleted.

CHECK

Have we achieved our goals?

The lead time from the start of production to shipment was reduced by 46%.

Limiting unnecessary movements and long routes helped reduce fatigue and the risk of injury for operators, improving safety and comfort during daily tasks. A more ergonomic environment also fosters greater focus and a more positive working atmosphere, directly impacting staff motivation and satisfaction.

The optimisation of production processes in the Delivery area has enabled Officina 3 to ensure more stable and predictable delivery times, reducing delays and inefficiencies. Greater reliability in delivery schedules has strengthened the relationships with high-fashion brands, who can rely on a partner capable of responding quickly and precisely to their needs.

Benefits Obtained

01

The benefits achieved positively influenced the team and triggered the process of continuous improvement in operations. The people, who immediately made themselves available by demonstrating a remarkable willingness to change, embraced the project with enthusiasm. It is people who bring results, and only by changing their behavior is it possible to succeed in transformation-this is the real difference between being lean and doing lean.

02

I benefici raggiunti hanno influenzato positivamente il team e innescato il processo di miglioramento continuo dell'operatività. Le persone, che si sono rese da subito disponibili dimostrando una notevole propensione al cambiamento, hanno accolto il progetto con entusiasmo. Sono le persone a portare i risultati e solo cambiando il loro comportamento è possibile avere successo nella trasformazione: questa è la vera differenza tra essere lean e fare lean.

From Delivery to Development

Following the results achieved and the high level of engagement in improving the Delivery macro-process, the Officina 3 team independently launched new initiatives, applying the skills acquired during the transformation. Improved Delivery performance prompted the company to extend optimisation to the Development macro-process as well, confirming its commitment to continuous improvement and increasingly efficient process management.

SCAN

Lean Gap Analysis® in Development

Reducing and stabilising lead time in sampling and prototyping was a priority. Where lead times are critical in mass production, they become even more crucial when developing prototypes and samples, where speed and precision are key.

Lean Gap Analysis®

An essential phase for measuring and analysing current processes and identifying the gaps between the present and desired states.

During this phase, a 'snapshot' of the current state of processes is taken, focusing on quantifying waste, identifying potential problems and opportunities for improvement, and timing all steps.

Gaining a clear understanding of process performance is crucial for determining the most effective countermeasures to eliminate the root cause of the issue, as well as for planning future actions and determining which KPIs to monitor to improve efficiency.

Identified gaps

01

Delays and punctuality in the world of samples and prototypes

As in the Delivery macro-process, delivery times for samples are also critical in Development. In this case too, delays and urgent shipments were recorded.

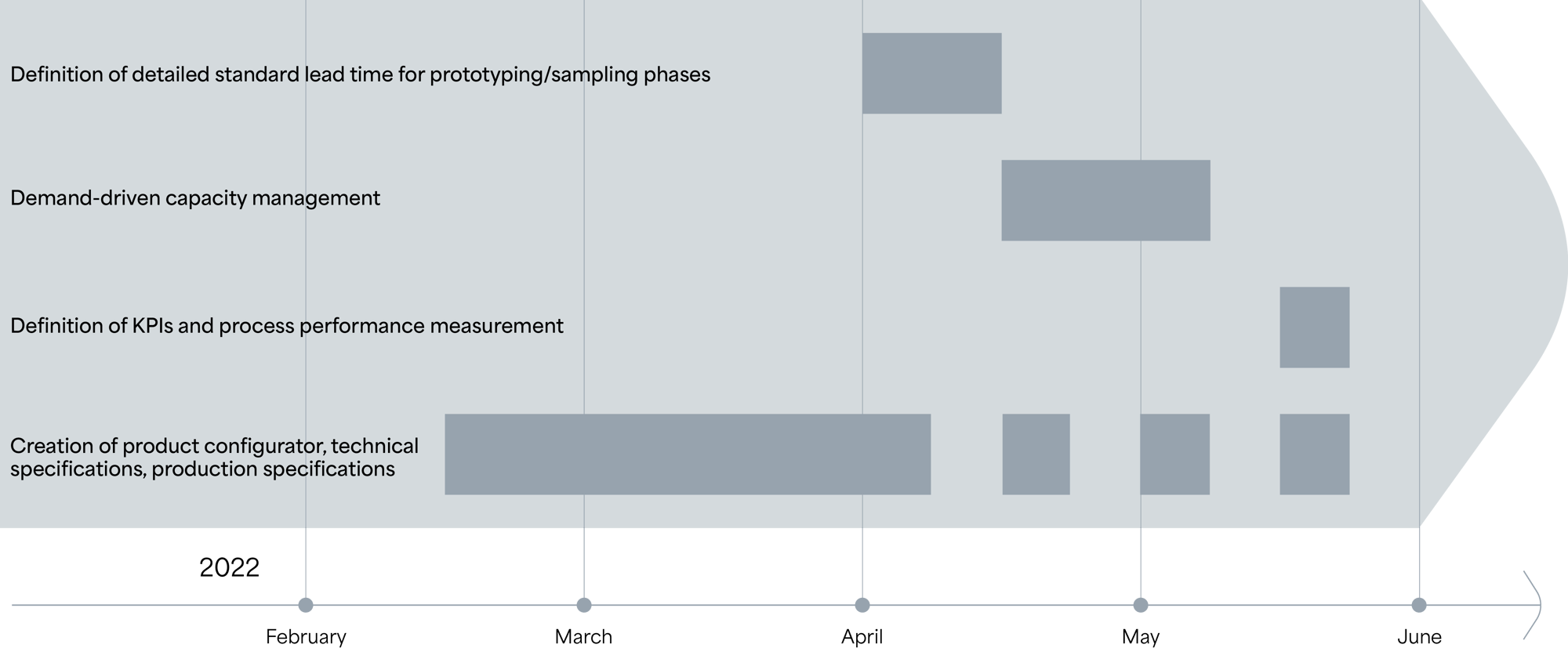

PLAN

Lean RoadMap® in Development

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN.

Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Officina 3 team.

The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective.

Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it.

The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

The path forward

01

Design of a heijunka system

A heijunka board was implemented at the entrance to the sampling area to level workloads on the sampling machines and to properly plan production in with the customer’s requested delivery dates.

Expected benefits

Reducing product development lead time

Increased production capacity of the development team

Riduzione lead time di sviluppo prodotto

Aumento capacità produttiva del team development

DO

Design for Simplification

Which lean activities and techniques enabled us to achieve our goal?

Heijunka implementation

The work steps of the sampling process were identified, and data on constraints and cycle times were collected. By implementing a visual board, planning visibility was provided to sampling operators, allowing them to organise materials and equipment well in advance. For this reason, orderly material management in the area is essential. The planning heijunka was complemented by floor visual management: the materials scheduled for processing on a given day were placed in a designated area. This eliminated the time operators spent searching for materials.

CHECK

Have we achieved the goals set?

The creation of tools such as the heijunka board and floor visual management was independently carried out by the Officina 3 team with expertise and proactivity, leveraging the knowledge gained during the transformation of the Delivery process.

Thanks to clearer priority management and the introduction of a pull system, sampling and prototyping now follow a more linear flow, without interruptions or bottlenecks.

The implementation of heijunka has improved sampling management by ensuring clear and structured planning. The visual board has provided visibility of activities, enabling materials and equipment to be organised in advance, while floor visual management has eliminated search times. The Officina 3 team applied these tools autonomously, consolidating the skills acquired during the Delivery process transformation. The result is smoother workflow, free from interruptions or backlogs, thanks to effective priority management and the introduction of a pull system.

From Development to Deployment

Building on the results achieved and the high level of engagement in improving the Development macro-process, the Officina 3 team independently initiated new projects, applying the skills gained during the transformation.

A concrete example is the independent adoption of hjeijunka and visual management tools, demonstrating strong management capabilities and a proactive attitude. The optimisation of Development has encouraged the company to extend improvements to the Deployment macro-process, further enhancing operational efficiency and continuous improvement.

SCAN

Lean Gap Analysis® in Deployment

The company, specialised in supporting high-fashion brands, needed to reorganise its strategy to enhance operational efficiency. The speed and variability of requests made it challenging to manage activities in a structured way, resulting in difficulties in setting priorities and optimising workflows. To address this, a reorganisation initiative was launched to streamline processes, ensuring quicker execution and more effective management of operations. The aim was to strengthen the company's position as a trusted partner in the high-fashion industry.

Lean Gap Analysis®

Essential phase to measure and analyse current processes and define gaps between the current and desired state. In this first phase, one goes to "take a picture" of the current state of the processes in terms of quantifying waste, identifying any issues and opportunities for improvement, and timing all the steps. Having a clear view of the performance of the process is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and to design, with a view to the future, the activities to be done-and on which KPIs to measure-to make it efficient.

Identified gaps

01

Lack of prioritisation of projects to be undertaken

While the strategic goals were clear to both management and ownership, the prioritisation and frequency of implementation of individual projects in relation to these objectives were not.

PLAN

Lean RoadMap® in Deployment

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN.

Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Officina 3 team.

The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective.

Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it.

The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

The path forward

01

Implementation of the A3-X

A tool aimed at defining projects relevant to the company strategy and correlating them to people, objectives, and key indicators.

Expected benefits

Increased level of alignment of projects with business strategy

Maggiore livello di allineamento dei progetti alla strategia aziendale

DO

Hoshin Kanri

Which lean activities and techniques enabled us to achieve our goal?

A3-X

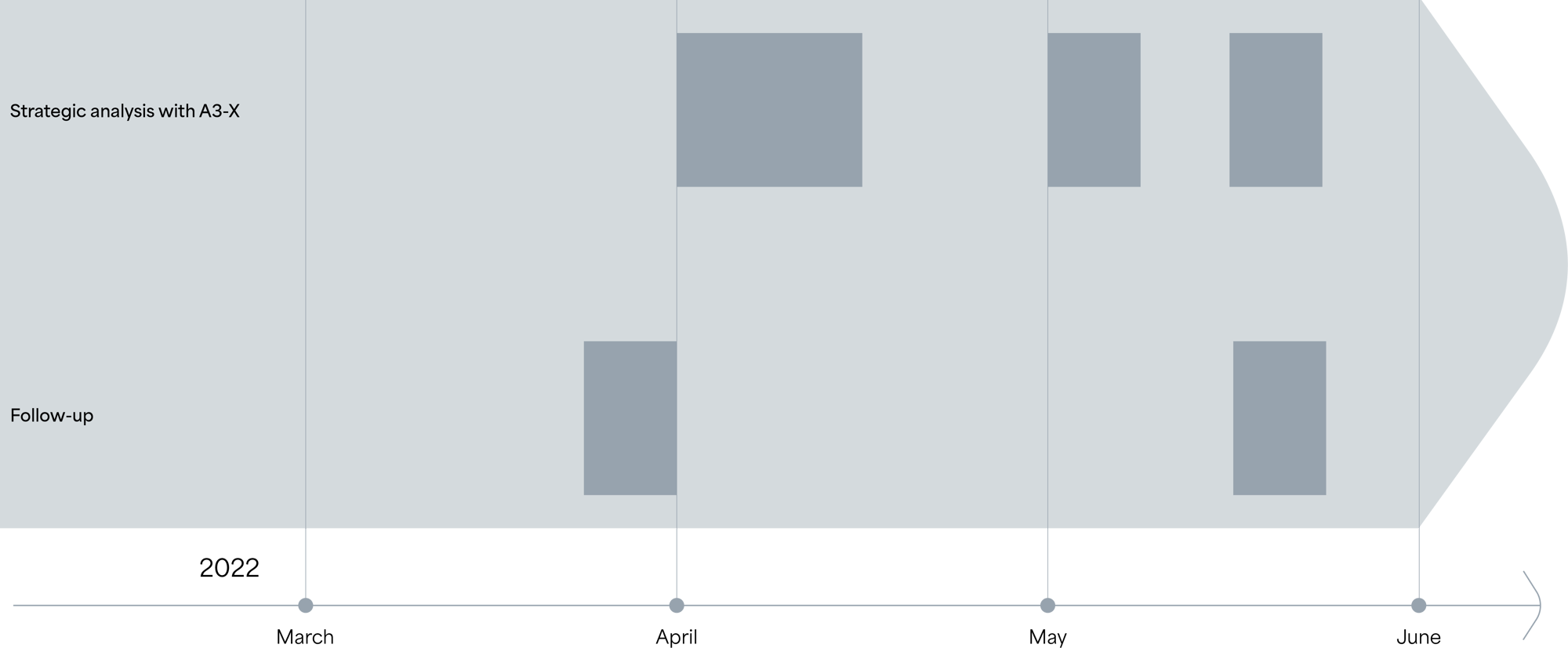

The company first defined its business strategies. Based on these, all major company-wide projects were defined, and – by aligning each project with the strategic objectives – the implementation priority of each was identified using a Gantt chart.

CHECK

Have we achieved our goals?

Strategic management optimisation was achieved through A3-X, a tool that enabled the selection of priority projects aligned with company objectives, the assignment of dedicated teams, and the definition of key performance indicators.

This approach led to the standardisation of weekly sprint meetings of the Hoshin team and the completion of strategic training and alignment for all first-level employees, ensuring greater consistency and focus on company objectives.

Greater alignment of projects with company strategy

From Deployment to future opportunities

The project in Deployment was the one that enabled all other projects in the other areas to move forward, now assessed as aligned with the company’s overall strategy.

Our experts are available to support your company through its transformation journey

Subscribe to our newsletter and receive exclusive content, practical tips, and updates delivered directly to your inbox!