05

Portfolio

Xylem

Intro

Definition of a structured model to select the logistics partner and regain ownership of inbound and outbound processes in just three months

Industry

Design of water cycle solutions

Headquarters

Washington D.C., USA

Subsidiaries

68 main production sites worldwide

Xylem, a leading company in water management technologies, chose to collaborate with our team to define a structured and objective model for issuing, in just three months, a tender to select a new partner to manage inbound and outbound logistics processes. In parallel, the project activated an internal programme to regain know-how and ownership of process improvement, while concretely evaluating the opportunity for future insourcing. This initiative saw the Xylem team take the lead in independently managing operational activities, with the aim of consolidating skills, increasing punctuality, and ensuring stable and measurable performance.

Performance achieved

0

Punctuality

0

Efficiency

0

New operators including 2 supervisors

0

Injuries

Cristina Zenere

Distribution Manager IDC Montecchio - Xylem

Valeria Carvisiglia

Shipping Supervisor - Xylem

Martin Lucatello

Demand Plan Manager - Xyelm

Do you want to improve your company's performance?

Company

history

2011

Xylem Inc. is a US-based company founded in 2011 and headquartered in Rye Brook, New York State, operating in the field of water technologies, primarily in the areas of water transport, treatment, and use in public, residential, commercial, agricultural, and industrial settings.

Today

A global leader in water solutions, Xylem is committed to promoting sustainable impact and empowering those who work with water every day. Xylem is able to provide tailored technological and innovative solutions that cover the entire water cycle. From moving, treating, and measuring water to optimising and maintaining water systems, Xylem works alongside customers to address their most critical challenges.

Employees (2023)

0Turnover (2023)

0

The challenge faced by Xylem

The Xylem team turned to auxiell to develop a structured, objective model aimed at issuing, within just three months, an invitation to tender for the search and selection of a supplier/partner to take on the management of inbound (raw material and semi-finished goods) and outbound (shipment of finished product shipment) logistics processes. In parallel, another area of the project aimed to recover know-how and, consequently, ownership of process improvement, enabling the team to consider re-internalising these processes in the future.

The starting point

The transformation of the first macro-process: Delivery

2022

– start of collaboration

with auxiell

End

Together with Xylem, we worked on defining the new logistics setup, simultaneously undertaking a complete review of inbound and outbound flows.

SCAN

Lean Gap Analysis® in Delivery

To analyse the current state of processes with the Xylem team, we initially undertook a project in the Delivery area, with a particular focus on the stages of raw material receipt and storage, and the shipment of finished products. We did not limit ourselves to identifying gaps in package handling activities, but – taking a broader process view – also analysed the products in the warehouse, challenging the underlying logistical-production logic.

Techniques used to identify GAPs:

Process mapping in logistics to identify all activities, distinguishing between elementary (independent) and variable activities (which depend on factors such as space, speed, frequency of implementation, type of object handled, etc.). In genba, for each of these activities, the lead time was measured, and a ‘reference multiplier’ driver was identified to size the logistics system required based on current and future volumes, then compared with the current number of people involved. This made it possible to scientifically and objectively identify and quantify gaps in the process. The sizing model designed and implemented was used to objectively and quantitatively assess the proposals received through the tender process.

In order to decide as objectively as possible, it was necessary to create a structured decision-making process:

1. Identification of decision-making criteria

2. Distinction between "must" (essential) and "want" (desirable) criteria

3. Assignment of relative weights to each criterion

4. Evaluation of the bids received based on the previously identified criteria

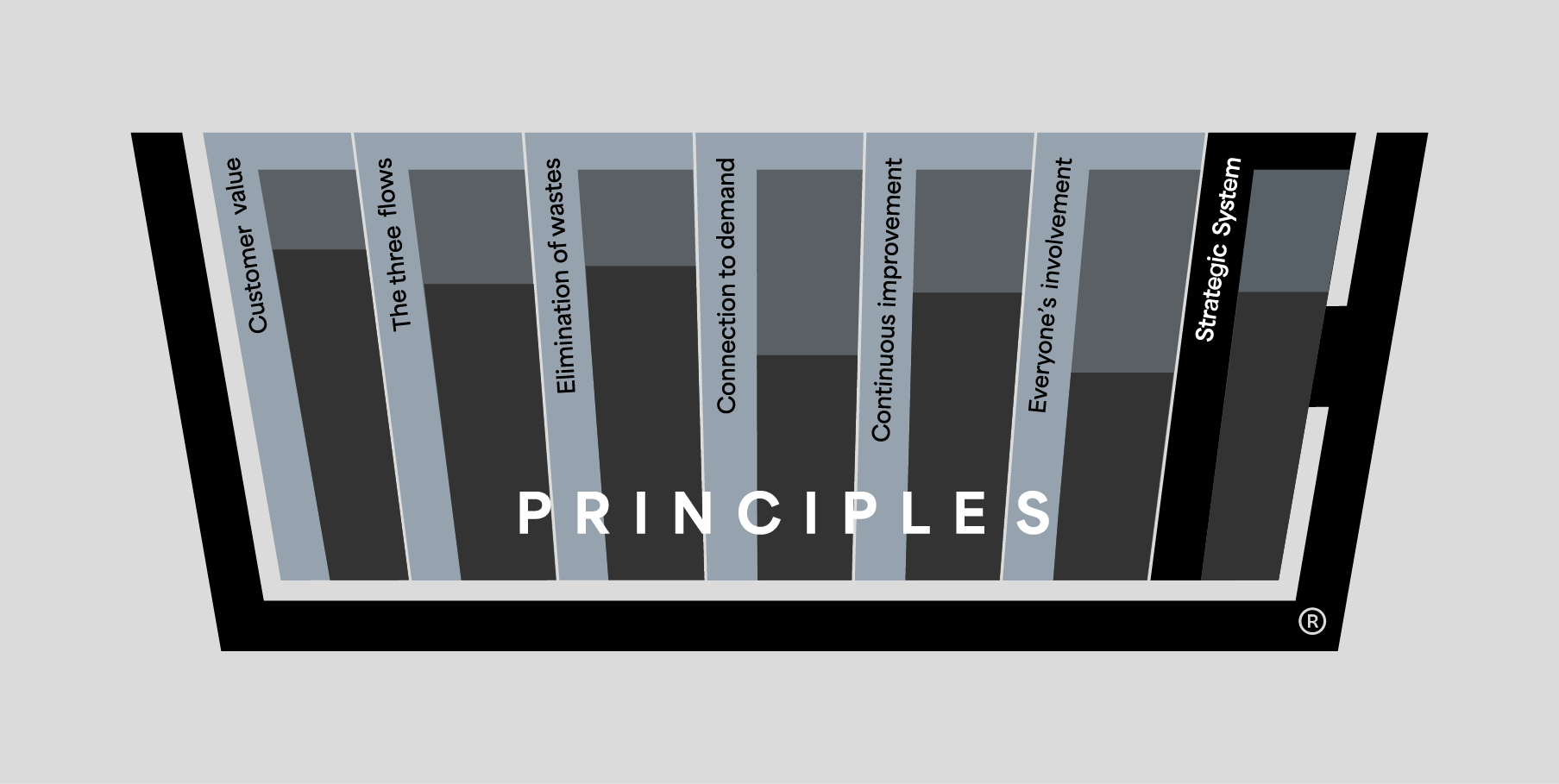

Lean Gap Analysis®

Essential phase to measure and analyse current processes and define gaps between the current and desired state. In this first phase, one goes to "take a picture" of the current state of the processes in terms of quantifying waste, identifying any issues and opportunities for improvement, and timing all steps. Having a clear view of the performance of the process is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and to design, with a view to the future, the activities to be done-and on which KPIs to measure-to make it efficient.

Identified gaps

01

Presence of a high number of non-value-added activities in logistics processes

The significant loss of nearly 50% of logistics operators' time in non-value-added (NVA) activities – such as waiting, empty transport, unnecessary movements, and searching for materials or information – resulted in delays and, more generally, a deterioration in customer service levels.

02

Failure to comply with previously established process standards

This caused operational times to extend beyond planned schedules, penalising overall process efficiency and the ability to ensure optimal performance.

03

Loss of knowledge and visibility across the entire process

Lack of awareness of the activities performed and process standards prevented verification of the appropriateness of rates paid to service providers. In the absence of objective parameters, negotiations were not always based on factual data, resulting in financial losses.

04

Customer service levels no longer aligned with business objectives

Performance shortcomings – including a decline in on-time deliveries and increased lead times – could potentially compromise customer management and the maintenance of high service standards, causing dissatisfaction and loss of credibility.

05

Perception of widespread issues in processes

Xylem identified excessive costs for services provided, without a corresponding level of quality or added value.

06

Misalignment between production and shipping

The lack of coordination between production and shipping, regarded as separate entities, led to potential misalignments and an hindered synergy creation. The absence of multi-skilled operators further exacerbated the situation.

07

Inefficient inventory management

Warehouse overloading caused operational slowdowns, also due to the separation between systems managing different process stages.

08

Missed improvement opportunities

Lack of control over activities and improvement initiatives led to inaction regarding suppliers. Processes remained unchanged, while optimisation opportunities were overlooked.

PLAN

Lean RoadMap® in Delivery

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN.

Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Xylem team.

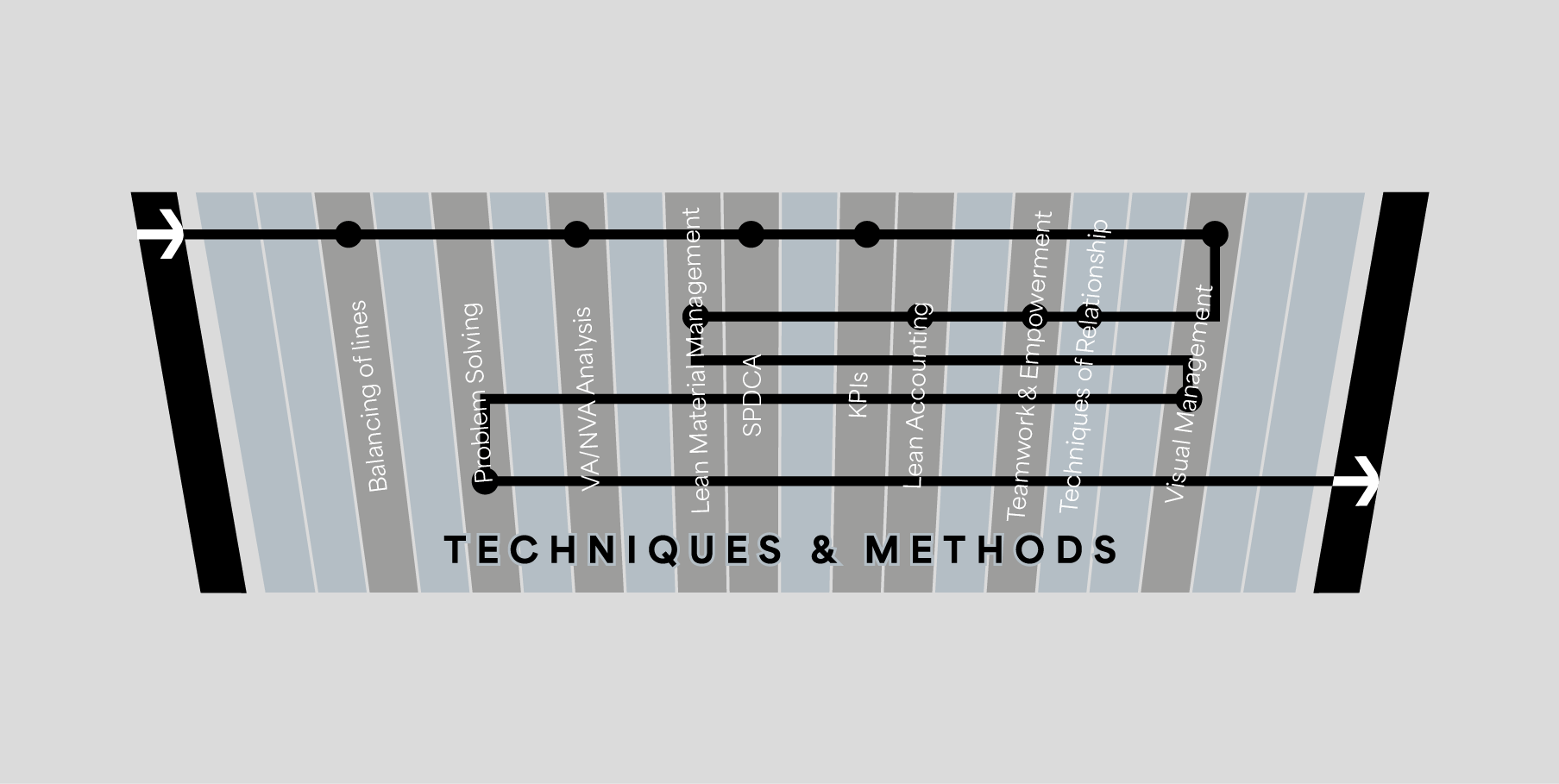

The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

This is the phase in which the future state of the analysed process is planned from a multi-scenario perspective.

Once the most appropriate scenario is chosen from a technical and economic standpoint, we move on to planning the steps to implement it. The Lean RoadMap® identifies the activities to focus on and the timelines for completing them.

The path forward

01

Process flow efficiency

With the aim of increasing efficiency in logistics operations, new standards were designed to balance the picking and packaging processes and to optimise the management of exchange areas.

02

Visual management

To simplify process management and ensure that the operational flow provides sufficient information to make informed decisions.

03

Definition of KPIs

To present a system of performance and process indicators and to identify the key drivers that enable decisions to be made to achieve target performance.

04

Problem-solving and continuous improvement

To investigate the root cause of obstacles that emerged during process optimisation and be able to remove them effectively, with a view to continuous improvement.

05

Flexibility and versatility of resources

To ensure the team's flexibility and versatility, it is necessary to initially design the distribution of skills according to the production flow, starting with a mapping of the current state to identify gaps in relation to the established objectives. The resulting versatility matrix then makes it possible to identify priorities and plan a targeted training programme, which is then delivered to address the identified gaps.

To measure and monitor progress, specific KPIs are defined and shared, accompanied by a structured monitoring and problem-solving process. This allows the level of versatility to be maintained over time through periodic reviews and initial support to develop independent management of corrective actions.

06

Analysis of current market response models, decoupling points, and logistics flow management

To ensure more efficient inventory management and optimal space utilisation, it is necessary to carry out an in-depth analysis of the system constraints that affect materials management. This will make it possible to identify critical issues and redesign processes to improve the smoothness and consistency of operations. In parallel, market response models, decoupling points, and logistics flows will be examined with the aim of aligning operational strategies with demand needs and optimising time and resources. Finally, action will be needed to address space saturation by reducing overloading and improving storage capacity to support a continuous and efficient flow.

07

Supply chain gap analysis and roadmap

To ensure continuous improvement in business performance, it is first necessary to measure the existing gaps between achieved results achieved and defined targets, focusing on competitive variables and adopting a process-oriented approach. This aims to accurately identify the main critical issues related to the supply chain, enabling the definition of a structured plan to support the adoption of flow and collaboration principles, which are essential for an integrated and efficient operations. Once the key action points are identified, targeted corrective measures are implemented, ensuring continuous alignment with business objectives.

Expected benefits

Reduced lead time from order to shipment

Adaptation of market response models

Increased punctuality on deliveries

Reducing the transportation of materials between stages

New plant layout design with a view to process efficiency

DO

Delivery Overall Transformation

Team leading the change

The Xylem team independently managed all the activities required for the transition, coordinating with the outgoing logistics provider and selecting the personnel to be involved in the new setup. An onboarding process, new training on safety, continuous improvement and leadership, and a field support plan through daily genba walks were established. The team updated operational standards, introduced new management tools, replaced equipment, and reorganized the workspace. New operational and coordination resources were introduced, the versatility matrix was updated, and a workforce model was implemented to monitor capacity and productivity. All activities were designed and implemented in-house, confirming the level of ownership achieved.

CHECK

Have the set goals been achieved?

For Xylem customers: punctuality has improved thanks to a 20% increase in OTD (on-time-delivery) and a reduction in lead time.

Customer-perceived quality has increased.

Productivity has increased significantly, from 52% to 75% efficiency.

Operating costs and emergencies have been reduced.

The skills of the team have been enhanced, promoting internal multifunctionality.

Order waiting times for suppliers have decreased.

Benefits Obtained

01

The benefits achieved positively influenced the team and triggered the process of continuous improvement in operations. The people, who immediately made themselves available by demonstrating a remarkable willingness to change, embraced the project with enthusiasm. It is people who bring results, and only by changing their behavior is it possible to succeed in transformation-this is the real difference between being lean and doing lean.

Concrete results and autonomy in driving change

The project represented a concrete opportunity for Xylem to strengthen control over logistics and operational processes, enhance internal expertise, and achieve measurable performance improvements. The team managed a complex transition autonomously and effectively, delivering tangible results in terms of punctuality, quality, productivity, and efficiency. This journey consolidated the organisation's ability to drive change, starting from shared standards and clear objectives.

Our experts are available to support your company through its transformation journey

Subscribe to our newsletter and receive exclusive content, practical tips, and updates delivered directly to your inbox!