We were involved by Smartech Italia-a company specializing in the production of customized cooking plates for professional kitchens-to start a pilot transformation project with the aim of increasing operational efficiency and supporting growth through more stable, streamlined processes connected to real demand. The initial focus was on theproduction area identified as a critical point for operational complexity and direct impacts on lead time and on-time delivery.

The intervention involved redesigning the production system according to pull flow principles-with finite capacity planning from the bottleneck-andeliminating inefficiencies in physical and information flows. A structured problem solving system was introduced while the layout was revised to reduce movement, improve linearity and free up production space. The project also included the extensive application of the SMED technique on milling, the introduction of supermarkets in kanban logic of finished product and raw material, and the activation of lean accounting to measure economic and operational performance in an integrated manner.

The result is a more orderly, flexible and responsive system-with materials available only when and where they are needed, optimized workstations and a team involved in improvement processes. As evidence of the excellent results achieved in the project, the Smartech Italia team was honored in 2017 in Stockholm as one of Electrolux's three most innovative suppliers worldwide.

Performance Achieved

0

average lead time

0

EBITDA in 10 years reaching over 20% of sales in 2024

0

daily punctuality index

0

monthly stock rotation index

Roberto Badin

General Manager - Smartech Italy

Silvia Girolami

Administration and Finance Manager - Smartech Italy

Fabio Napoli

Planning and Production Manager - Smartech Italy

Nicholas Flower

Lean Agent - Smartech Italy

Do you want to improve your company's performance?

History

company

2001

Smartech Italia was founded in 2001 in Villotta di Chions (PN) from the technical and industrial experience gained in the professional catering sector-the initial goal is to provide tailor-made solutions for industrial kitchen manufacturers-from the beginning, the company has focused on product innovation, design flexibility and direct collaboration with customers to produce high-performance, reliable and customized cooking plates.

Today

Today Smartech Italia manufactures customized cooking plates for leading professional kitchen manufacturers - it offers complete solutions: from prototyping to production and logistics - it works to customer specifications ensuring adaptability, production continuity and consistent quality. It is organized with a streamlined production area, structured according to Lean principles-a sales network oriented to direct collaboration with OEMs and international partners-every step of the process is tracked and monitored to ensure certain timing and maximum efficiency.

Employees (2024)

0Turnover (2024)

0EBITDA (2024)

0

The challenge of Smartech Italy

Ensure continuity and flexibility in production by eliminating interruptions, waiting, and non-value activities-in an environment characterized by frequent shifts, lack of operational standards, and unsynchronized work logics with the goal of improving efficiency, production capacity, and quality of the work environment.

The starting point

The transformation of the first macro-process: Delivery

2012

Year start collaboration

with auxiell

The collaboration continues

The project in Delivery has brought concrete benefits both on the efficiency of the production process and, consequently, in the economic performance of the period.

The transformation of the first macro-process: Delivery

The streamlining of accounting processes

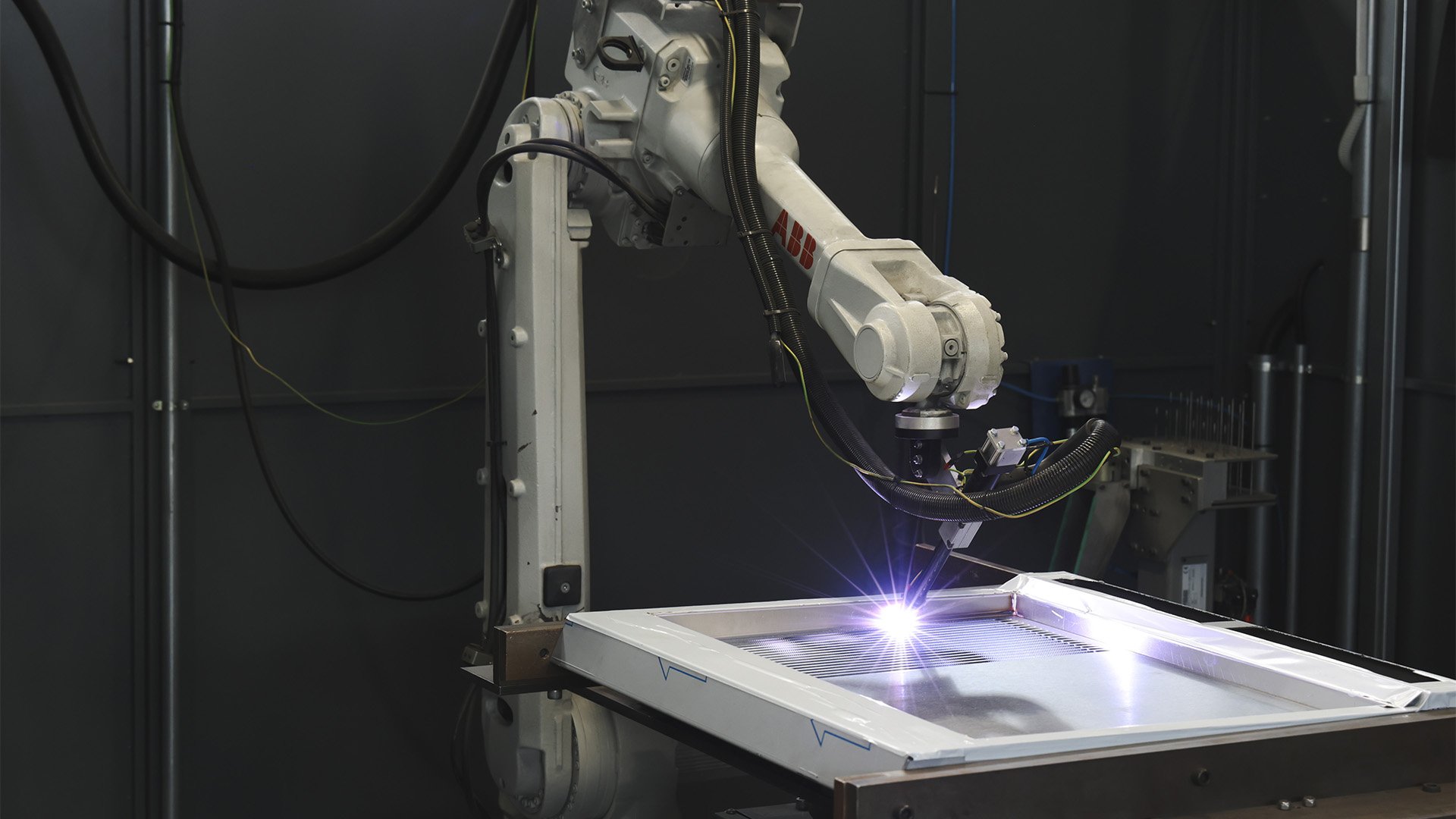

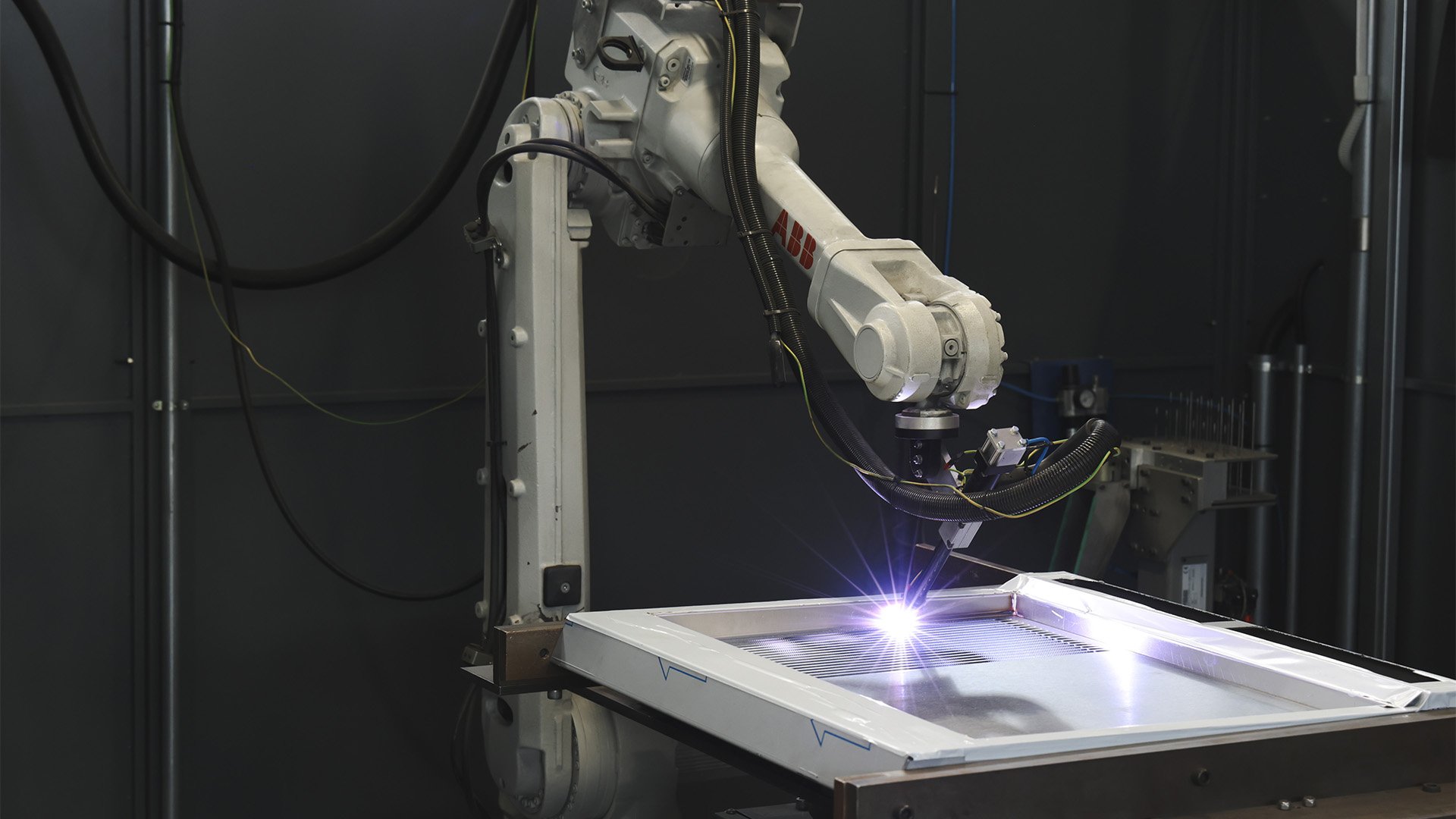

The project involved the entire production process-from order entry to shipment-of plates. At the initial stage, the system was characterized by batch production, common equipment and lack of standards - conditions that generated interruptions, waiting and production disconnected from customer demand. The intervention focused on the reorganization of the internal production flow, with particular attention to critical locations for capacity and variability. The work involved both physical and information flow, acting in an integrated manner on materials, layout, methods, and demand management. The stages involved in the flow include: material replenishment, sheet metal cutting, straightening, milling, polishing, welding (manual and robotic), and satinizing.

SCAN

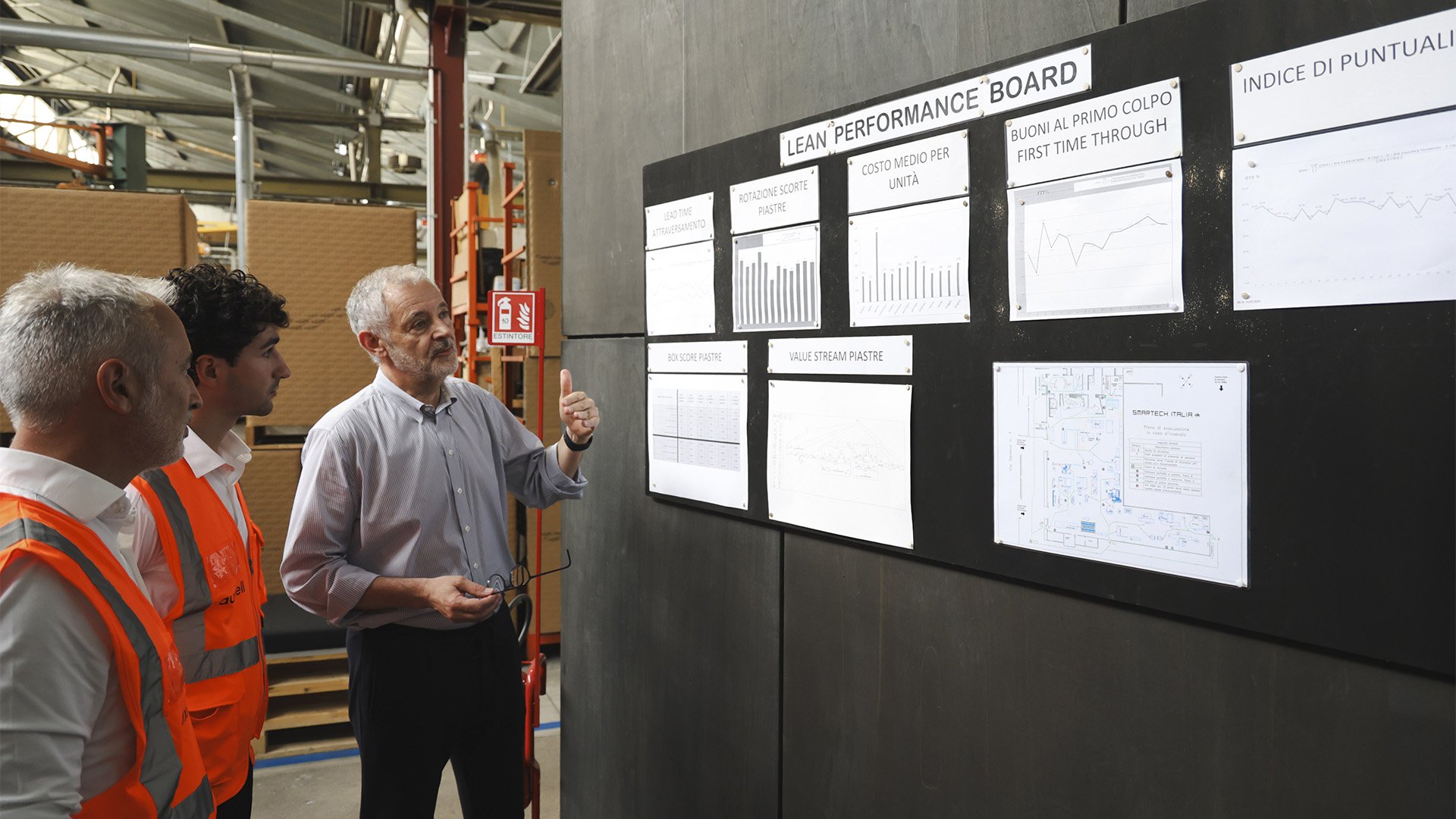

Lean Gap Analysis® in Delivery

To analyze the current state of the processes, the auxiell-Smartechteam engaged in Lean Gap Analysis®.In this first phase , the team worked to "take a picture" of the current state of the production process-from the moment the order arrives until the product is shipped to the customer.

Lean Gap Analysis®

Essential step to measure and analyze current processes and define gaps between the current and desired state. In this first phase, one goes to "take a picture" of the current state of the processes in terms of quantifying waste, identifying any issues and opportunities for improvement, and timing all steps. Having a clear view of the performance of the process is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and to design, with a view to the future, the activities to be done - and on which KPIs to measure - to make it efficient.

The gaps that emerged

01

Interruptions in production flow - Operators forced to stop work to find material for processing

The material needed for processing was not always available near the workstation - generating continuous interruptions to the flow and reducing the overall efficiency of activities.

02

Unnecessary movements and steps - Widespread presence of activities without added value

The process included unnecessary moves, transportation and steps - unnecessary activities that increased time and reduced productivity.

03

Excess consumables and spare parts - Space occupied by stock not commensurate with requirements

Large quantities of consumables and spare parts were stored near production - saturating the area and hindering the management of truly critical components.

04

Absence of standards - High search times and impact on operational well-being

Lack of standards of order and cleanliness generated disorganization-with prolonged times in searching for tools and materials and an environment perceived as neglected, negatively impacting motivation.

05

Shared stages and common equipment - Complexity in management and frequent waits

Sharing equipment and locations among different workings resulted in operational overlaps - increasing WIP and generating unscheduled waits.

06

Intermediate stocks not linked to customer demand - Batch production.

Pending plates between stages were present even in the absence of customer demand - feeding a pushlogic and an increase in intermediate stocks. Production was thus dependent on the time of order and multiple orders were merged to make a larger batch thus generating misalignment with demand.

07

Lengthy and non-standardized setups - Long waits and large batches

Setup times varied significantly and did not follow codified procedures - incentivizing large batch productions to compensate for downtime and generating response time inefficiencies.

PLAN

Lean RoadMap® in Delivery

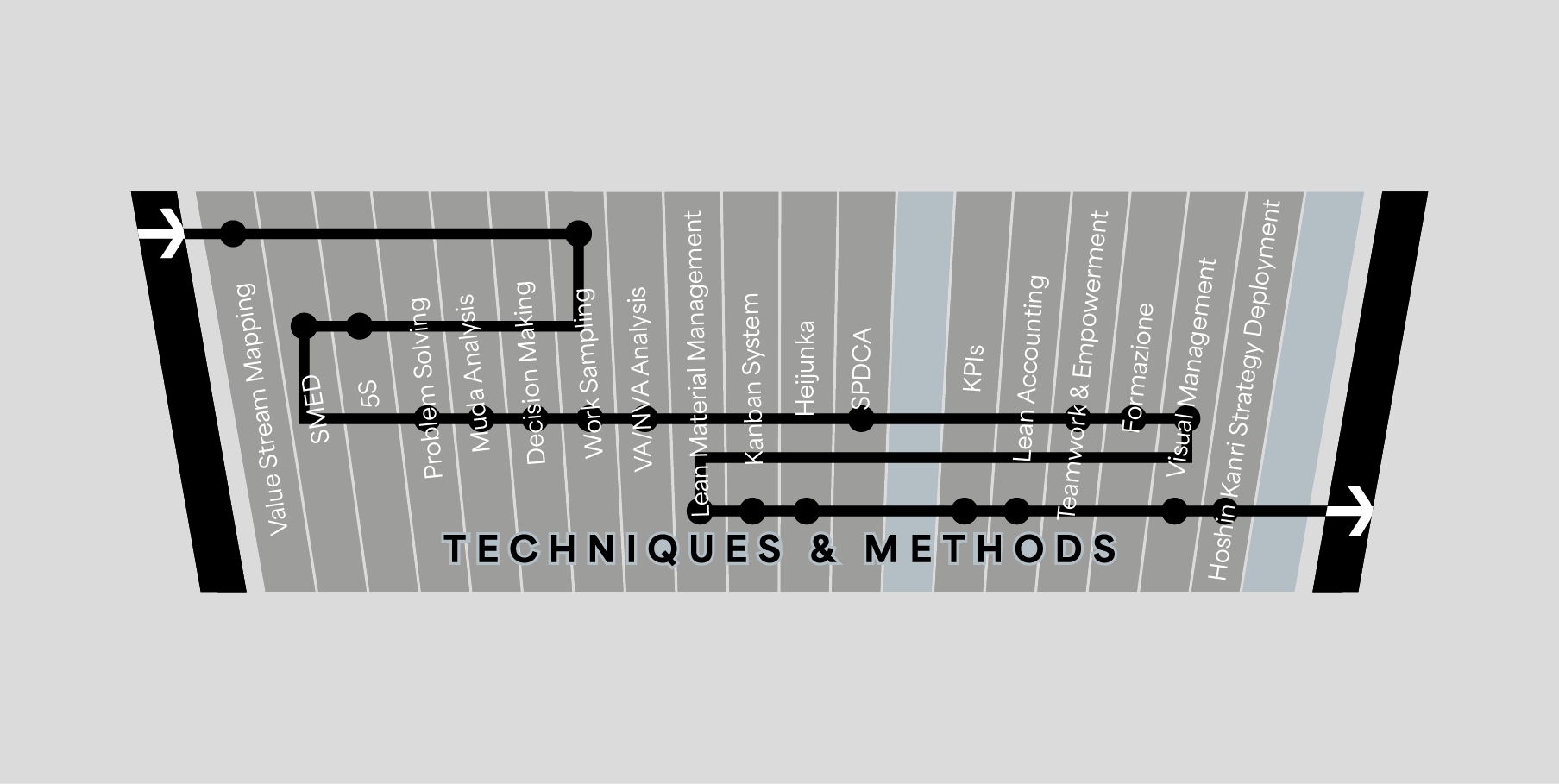

Once the gapswere identified, we moved on to the next phase of the project, which is the PLAN phase. Through the Lean RoadMap® we defined the sequence of implementation of the most correct leantechniques that would allow us to achieve the goals agreed upon with the Smartech Italiateam.

Lean RoadMap®

Stage in which the future state of the analyzed process is planned from a multi-scenario perspective. Once the most technically and economically correct scenario is chosen, we move on to planning the path to be taken to achieve it. In the Lean RoadMap® emerge the activities to focus on and the timeframe with which to complete them.

The direction to go

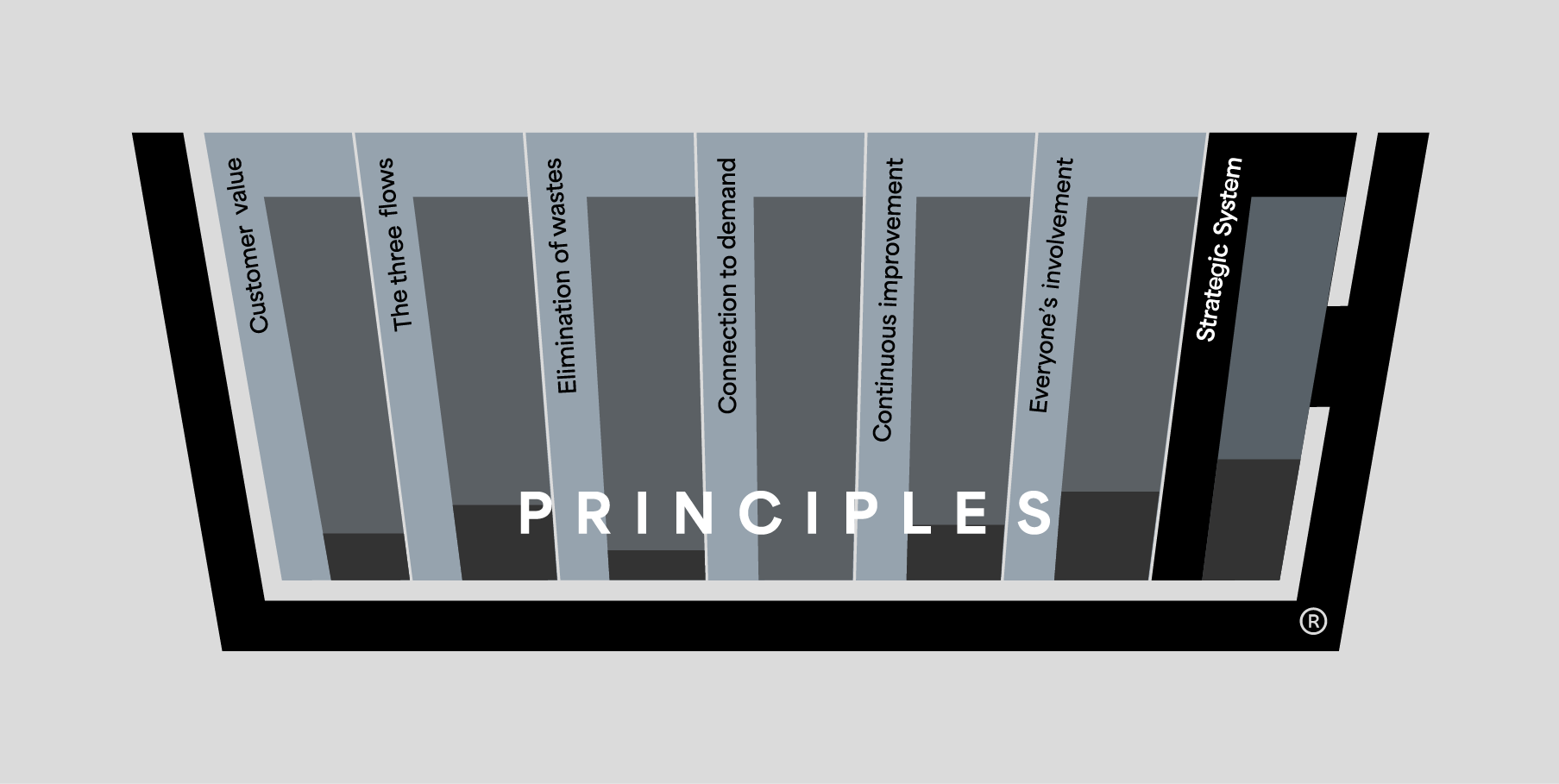

01

Lean culture

To create and spread leanculture and improve processes through people involvement and theoretical and practical training on lean system principles and techniques .

02

5S

The application of the 5S method in and around production workstations has been aimed at improving order, visibility and cleanliness-to reduce search time and increase operational readiness-as well as making the environment more usable and helping to improve the team'sperception of well-being and motivation .

03

SMED

Methodology introduced to reduce setup times-previously uncoded-and decrease the need for high batch production. The standardization of activities of also allows for increased production flexibility.

04

Relayout

The goal was to redesign the layout of workstations, materials, and equipment to simplify routes, reduce unnecessary movements, and create a seamless flow of activities, increasing the efficiency of the internal logistics system.

05

Lean accounting

Applied methodology to introduce continuous control and improvement tools to monitor process performance, production capacity and economic-financial impacts--making it possible to consistently assess operational efficiency and economic sustainability.

06

Review of production flow in pull (internal ) logic.

To link different production stages in pull logic, avoid intermediate accumulations and reduce waiting - favoring a balanced, continuous flow driven by real customer demand.

07

Linking to customer demand through kanbanpulls

With the goal of aligning production with actual customer orders through a kanban system-to increase on-time delivery, reduce lead times, and limit overproduction.

Expected benefits

Reduced lead time from order to shipment

Adaptation of market response models

Increased punctuality on deliveries

Reducing the transportation of materials between stages

New plant layout design with a view to process efficiency

DO

Delivery Overall Transformation

What lean activities and techniques enabled us to achieve the set goal?

Lean culture

An organization-wide training course-focused on leanprinciples and the 5S technique-has been activated to align operational language, increase awareness of expected behaviors, and support the widespread adoption of continuous improvement .

5S

The 5S technique was applied extensively, involving the entire company-from line operators to management-with the clear example of the president actively participating, contributing to cleaning activities in the factory. The intervention was the trigger to activate continuous improvement throughout the plant, generating a first level of standardization and creating the conditions for subsequent structured actions.

SMED

The SMED technique was applied to the milling stage-identified as the bottleneck-to reduce setup times for the three milling machines present. The goal was to increase the production availability of the critical machines and smooth the transition between machining operations, reducing batch and waiting times. The main benefit achieved was to make the production of any batch economically viable-thanks to the almost complete elimination of setup times. This made it possible to align batches with actual customer order sizes, reducing intermediate inventories and increasing system responsiveness.

Relayout

The layout was redesigned to improve the usability of the stations and simplify the flow of the plate, which previously followed a complex and articulated path. The intervention reduced displacement, eliminated counterflows and increased the overall linearity of the process.

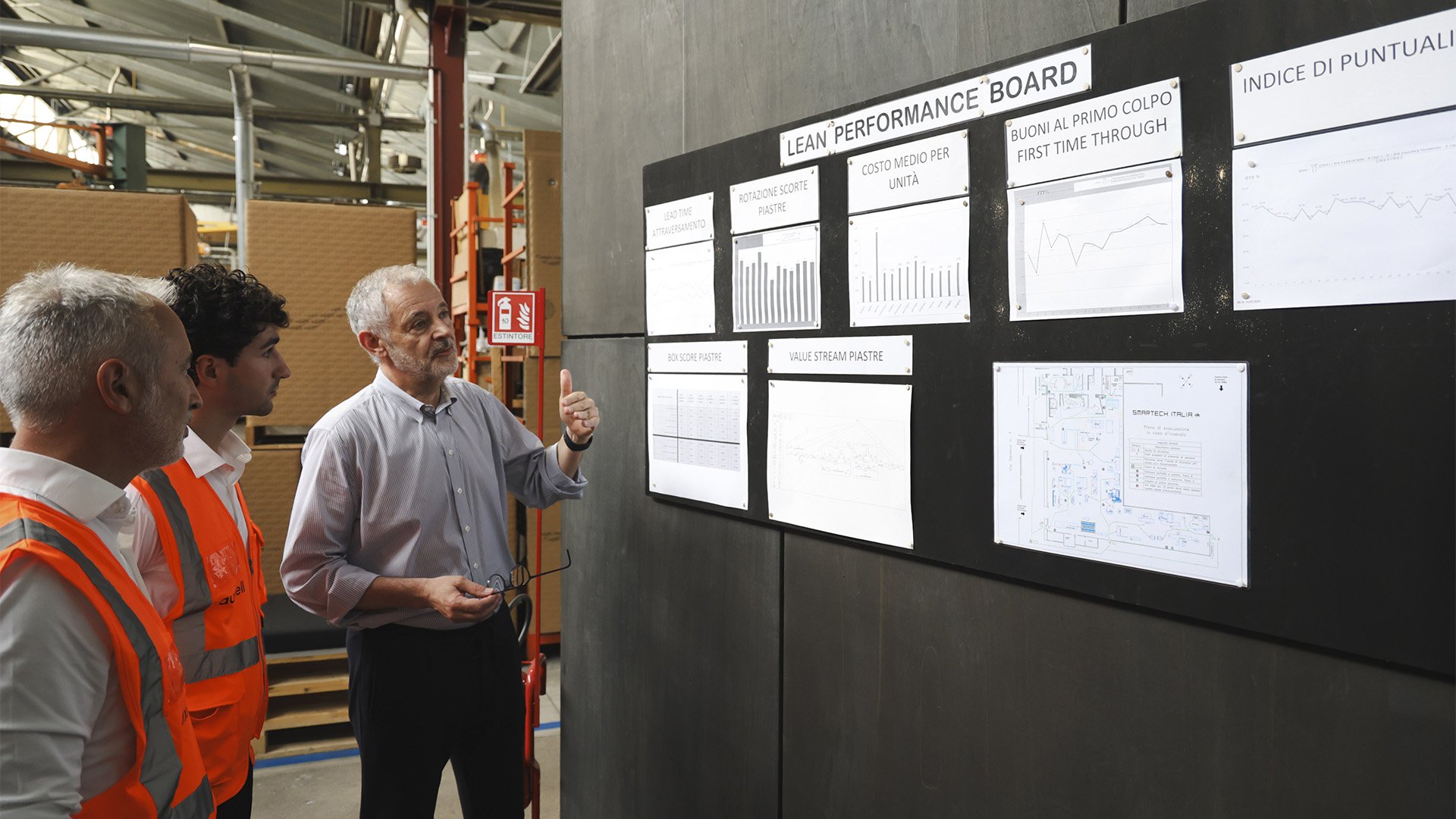

Lean accounting

Process KPIs were defined consistent with business strategy and monitoring tools were constructed based on box score. The profile of productive, non-productive and improving capacity was plotted, tying it to the value stream of the plate flow. A process income statement capable of allocating direct costs in the correct decision period was also constructed - enabling a more effective control system geared toward continuous improvement.

Review of the production flow from a pull (internal ) perspective.

The scheduling of activities was reorganized from the bottleneck using the heijunkatool - linking in pull logic the earlier stages and applying the FIFO rule for the later ones. The intervention reduced WIP accumulation and improved the operational balance between stages.

Linking to customer demand through pull kanban

A supermarket was created for high-rotation products, with the goal of ensuring availability of finished product within three days of customer demand. The kanbansystem made it possible to make actual requirements visible and synchronize production with demand, improving punctuality and service level.

Expected Benefits

CHECK

Have we achieved the goals set?

The application of the 5S throughout the plant has generated widespread order and cleanliness - making operational activities smoother and activating a continuous improvement process driven by the direct involvement of all functions.

The application of the SMED technique on the critical milling stage has resulted in a significant reduction in setup time-directly impacting flexibility and reducing the average production batch by 70 percent.

Relayout of workstations and processing routes has improved linearity of flow-contributing to a 46 percent reduction in lead time (from order to shipment) and greater efficiency in internal movements.

The introduction of a planning system in pull logic has made possible a better alignment between production and customer demand-increasing the level of on-time delivery (value being updated).

The introduction of the lean accountingsystem has made process performance visible and has contributed to more effective management of production capacity - with a direct impact on EBITDA, which has grown 4.4 times over the baseline period.

The project was recognized as an internal reference and used by the team to activate similar initiatives in other group plants - replicating the method and tools implemented.

From Delivery to Future Opportunities for Improvement

The Smartechproject has generated concrete results on efficiency, punctuality and economic sustainability. The application of 5S across the plant has improved order and organization-activating continuous improvement. Adoption of the SMED technique on milling has reduced setup time and lowered the average batch by 70%. Relayout of stations simplified the flow, reducing lead time by 46%. Implementation of pull flow has improved alignment to customer demand-with an increase in on-time (value being updated). The introduction of lean accounting enabled integrated performance monitoring, contributing to a 4.4-fold increase in EBITDA. The project is now used as an internal model. For its work, the Smartech Italiateam was honored in Stockholm as one of the three most innovative suppliers worldwide.

Our experts on hand to guide your business to transformation

Sign up for our newsletter and receive exclusive content, practical tips and news straight to your inbox!