07

Portfolio

Marcoling Covering

Intro

Marcolin Covering's challenge was twofold: to redesign the layout and, in general, improve production performance.

Industry

Manufacture of transport covers and event tent covers

Headquarters

Pordenone, Italy

Marcolin Covering faced a twofold challenge: redesigning the layout and, more broadly, improving production performance. The significant increase in sales volumes in 2019 led to extended lead times for deliveries and shipments. It was therefore necessary for the company to take action to realign with the timelines required by the market. The purchase of a second production plant and the need to define its layout created additional stress and internal conflicts between departments. This situation was further complicated by the imminent arrival of a major machine, which had to be placed in its final position within a month. This need led to the first contact with the auxiell team: first, the processes had to be designed, and then the layout was defined. Once the new layout was correctly implemented on schedule, lead time was halved from 10 to 5 working days, and punctuality improved by 19%.

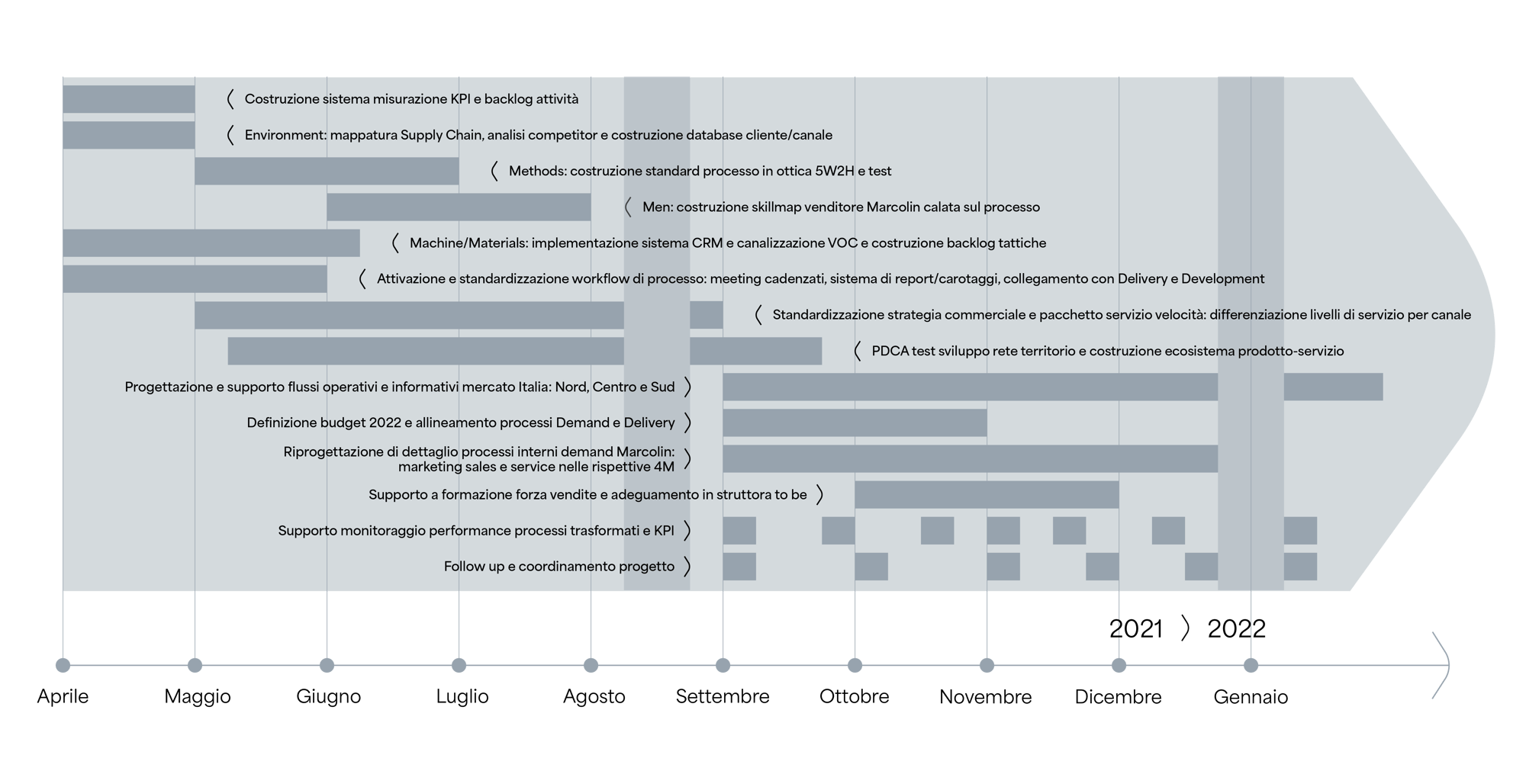

Building on the success in Delivery, the focus then shifted to Demand, with an emphasis on engineering and standardising the sales process to make it measurable, controllable, and more efficient. The objective was to increase its effectiveness, efficiency, and scalability to support the company’s growth.

In Development, efforts were directed towards accelerating product development to meet market speed requirements and maximise the impact of innovations.

Despite individual optimisation of the Delivery, Demand, and Development macro-processes, there was still a lack of overall alignment – three high-performing ‘engines’ that were not yet fully integrated. The Deployment phase completed the lean transformation, aligning processes with the company strategy and fostering a culture of innovation and continuous improvement across all levels of the organisation.

Performance Achieved

0

Production lead time

0

on-time delivery

0

incomplete orders

(without extra shipments)

0

turnover in 6 years

Federica Sartor

CEO - Marcolin Covering

Genes Della Libera

Delivery Manager - Marcolin Covering

Massimiliano Colussi

Development Manager - Marcolin Covering

Alessio Giusti

Demand Manager - Marcolin Covering

Do you want to improve your company's performance?

Company

history

1968

Marcolin Covering was founded in 1968 in Pordenone, where it is still located today with three production plants. It specialises in the processing of PVC, a technical fabric that can be used to make a wide range of products. Over the years, it has also added in-house production of mechanical components to create increasingly complex products.

In 2019, the company undertook the transformation of its processes with a focus on lean and agile management, achieving significant results in terms of reduced delivery times, costs, and improved quality. The project involved all the company’s collaborators, placing the company's values at the centre of the processes.

The Research and Development process has enabled the company to be the leader in the industrial vehicle cover sector today, in terms of product and process innovation, with a series of patents active throughout Europe. The company’s core business is the design, sale, and installation of transport covers for the European market. Another important sector is the rental and sale of modular tensile structures and accessories for public and private events, logistics, industry, and sport.

Employees

0Turnover (2023)

0EBITDA (2023)

0

Marcolin Covering’s challenge

Marcolin Covering faced a twofold challenge: redesigning the layout and, more broadly, improving production performance.

The starting point

The transformation of the first macro-process: Delivery

2019

Year of start of collaboration

with auxiell

2022

End

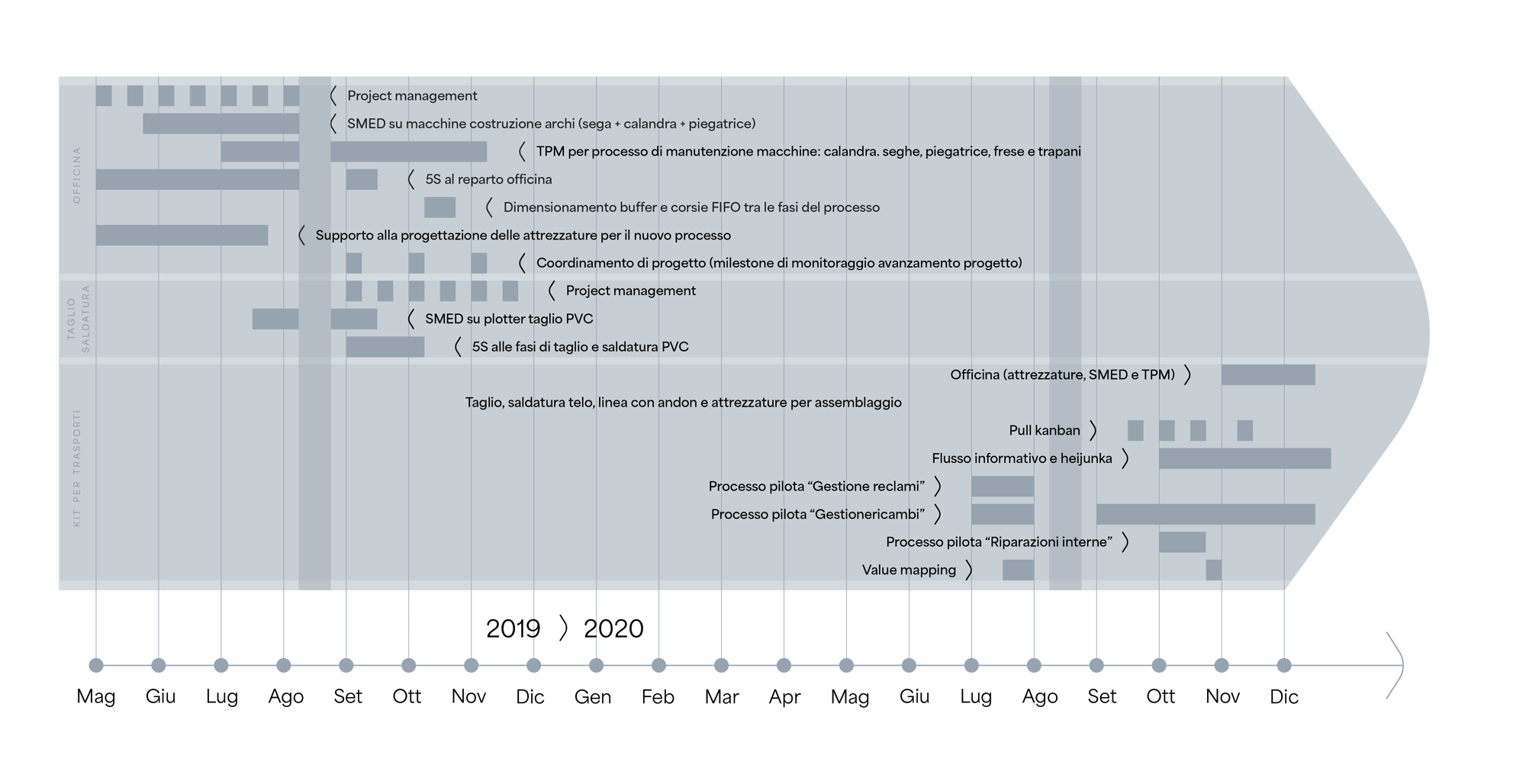

With the Marcolin Covering team, while designing the layout of the new plant, we worked simultaneously on the entire Delivery macro-process.

Following this, we shifted the focus to the Demand macro-process, which involves sales and demand management. Specifically, we refined the sales process to enhance efficiency and optimise the previously freed-up production capacity. Additionally, the project aimed to gather customer needs and transfer key insights to the R&D team to develop products that effectively meet their requirements.

After optimising the Delivery, Demand, and Development processes, we undertook a project on the Development macro-process, focusing on the creation of new products and modifications to existing ones.

After improving the efficiency of the Delivery, Demand and Development processes, we undertook a project on the Deployment macro-process, which involves translating strategies into coordinated activities.

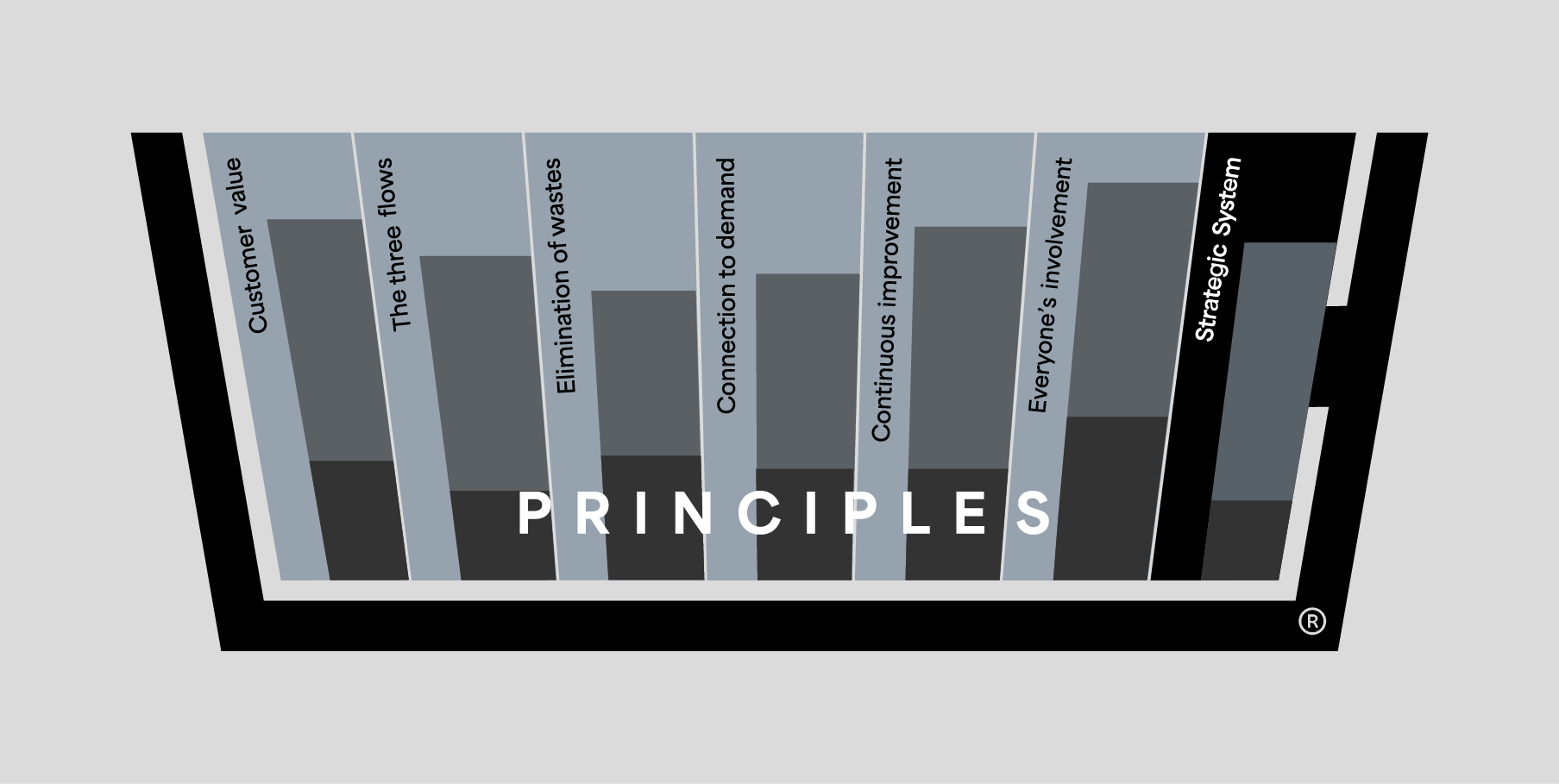

SCAN

Lean Gap Analysis® in Delivery

To analyse the current state of the processes, the auxiell-Marcolin team carried out a Lean Gap Analysis®. In this initial phase, the team worked to ‘capture’ the current state of the production – from the moment the order is received to the shipment of the product to the customer.

Lean Gap Analysis®

An essential phase for measuring and analyzing current processes and defining the gaps between the current state and the desired one. In this first phase, we “photograph” the current state of the processes in terms of quantifying waste, identifying any problems and opportunities for improvement, as well as timing all phases. Having a clear vision of the process performance is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and designing, with a view to the future, the activities to be done – and which KPIs to measure – to make it more efficient.

Identified gaps

01

High effort required to manage and plan the activities of individual departments

The production process was initially managed on a departmental basis. Department heads invested significant time coordinating activities, assigning tasks, and focusing only on the efficiency of individual process phases.

02

Excessive material movement between phases

The departmental structure of the production process required frequent material transport between phases.

03

Insufficient warehouse space

Overproduction of semi-finished products led to excess stock and occupied potentially reusable space.

04

Overproduction in anticipation of unexpected machinery maintenance

Machinery breakdowns and malfunctions disrupted production flow. These disruptions were compensated for through overproduction and stockpiling.

05

Frequent rescheduling due to urgent requests

Despite differing delivery time requirements, all orders were handled the same way, causing urgent requests and production delays.

PLAN

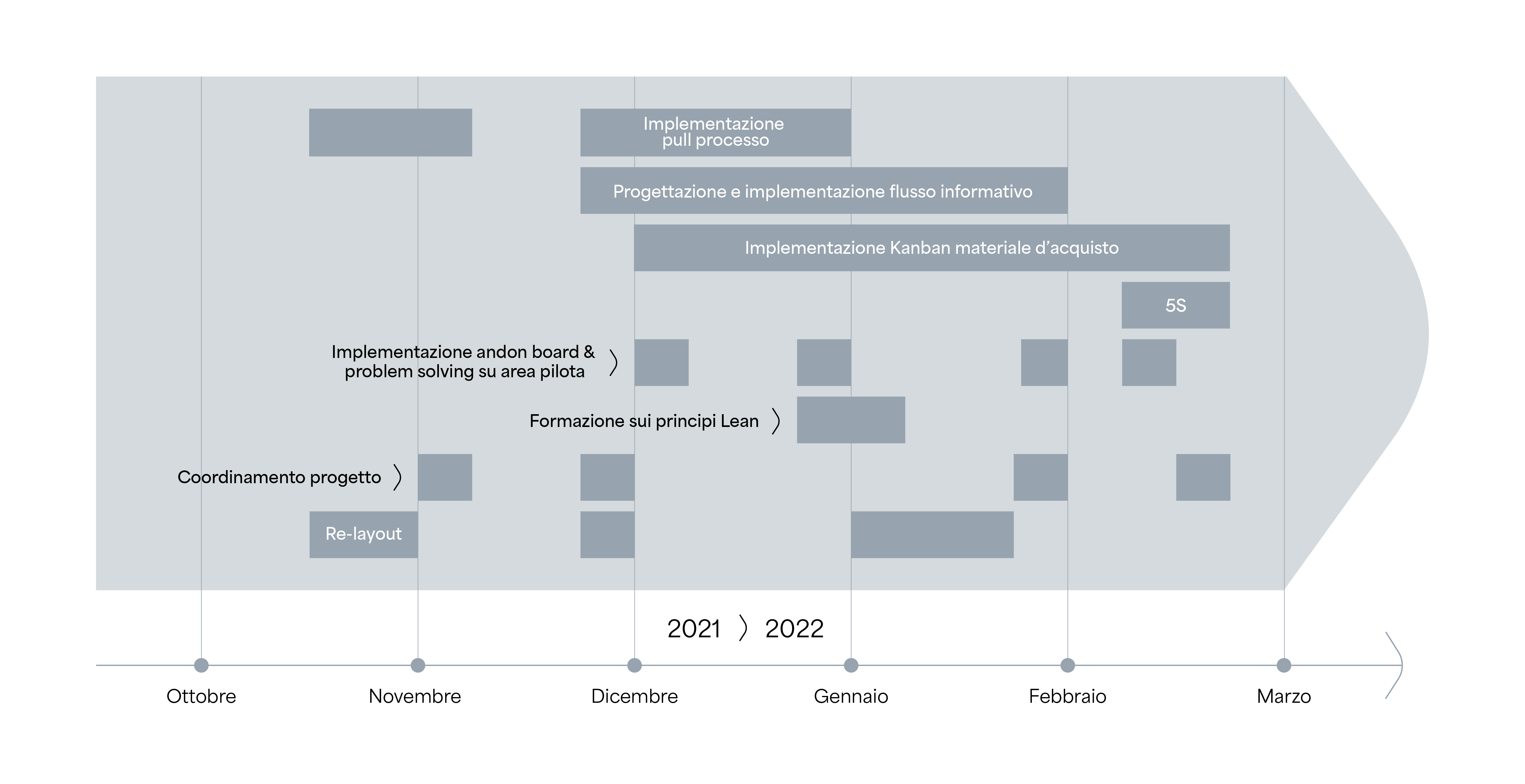

Lean RoadMap® in Delivery

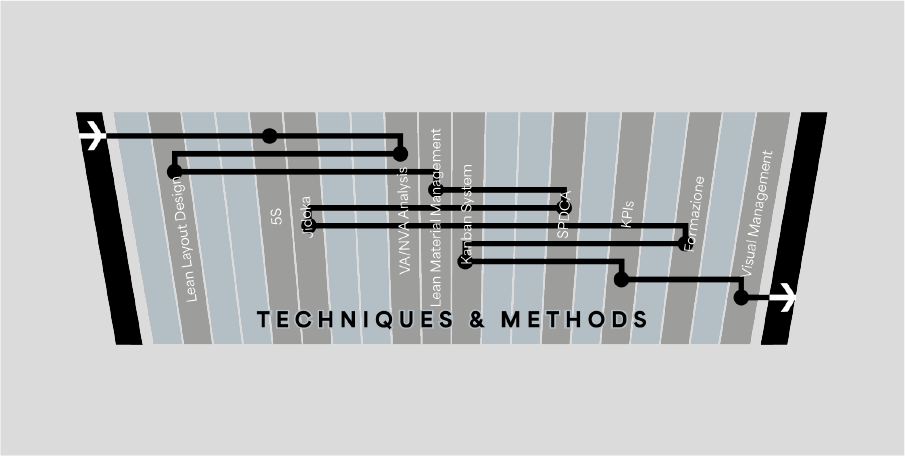

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Marcolin Covering team. The Lean RoadMap® outlines the techniques and methods applied throughout the project

Lean RoadMap®

Phase in which the future state of the process analyzed in a multi-scenario perspective is designed. Once the most correct scenario from a technical-economic point of view has been chosen, we move on to planning the path to take to achieve it. The Lean RoadMap® shows the activities on which to focus and the timeframes in which to complete them.

The path forward

01

Lean layout

To design the best possible layout – both macro and micro – from a multi-scenario perspective, considering the requirements and constraints of the new plant. In this phase, it was essential to involve the team in defining the various possible scenarios. The best choice was made through an objective evaluation of the musts and wants, thus removing subjectivity and conflicts.

02

Lean project management

A technique applied to support the team in implementing the new layout.

03

5S

To involve the team, promote a culture of order, and transfer the necessary materials to the new plant, starting it up with the new standards. This technique was applied in both the new and old plants, including the offices. The entire Marcolin Covering team – both managers and operators – participated in the activity.

04

SMED

To reduce set-up times in phases that generated overproduction by linking them together and creating a continuous process flow.

05

Pull system

To connect the phases of the process in FIFO mode where possible and implement Kanban logic between internal phases, also linking them to external phases in relation to suppliers.

Expected benefits

Reduction of lead time from order to shipment

Adaptation of market response models

Increase in punctuality of deliveries

Reduction in material transport between phases

Layout design of the new plant with a focus on process efficiency

DO

Delivery Overall Transformation

Which lean activities and techniques enabled us to achieve our goal?

Lean layout

The detailed layout of the individual workstations was designed and implemented with the involvement of the team.

Lean project management

The layout of the new plant was designed using project management guided by lean principles, a necessary technique for effectively managing unforeseen events and decisions related to the details of implementation. The process redesign then led to its sizing: each area was sized based on expected production volumes and the connection between the phases. To better visualise it, the new layout was initially positioned on a greenfield site and then integrated into the new building, taking architectural and logistical constraints into account. Among the various scenarios that emerged, the optimal one was selected based on objective considerations.

5S

The Marcolin team – consisting of operators and managers – responded with engagement and enthusiasm to the activities applying the 5S technique to organise and clean the workspaces in both the offices and the new and old plants.

The training sessions on the technique involved the team in lectures and experiential games. Thanks to their participation in the 5S application activities, the management and directors were able to experience firsthand the challenges and critical issues of the operational team, gaining a thorough understanding of them.

SMED

A tooling technique applied to centres with long set-up times that created obstacles to the flow of operations. In addition to analysing and redesigning the set-up times, considerable work was done to simplify operators’ tasks, making them less tiring, and to eliminate the variables that made the set-up unstable.

Pull system

By reorganising the process from a pull perspective, the downstream phase ‘signals’ to the upstream phase what and how much to supply – specifically for the assembly phase.

Skills and growth plans

The evaluation and growth metrics for individuals were redefined to align personal growth in terms of skills, capabilities, and values with the company’s improvement. To foster growth, it is essential for individuals to be multifunctional, possessing the knowledge and skills to take on different roles.

CHECK

Have we achieved our goals?

The company successfully positioned the new layout within the agreed time frame.

Lead time was significantly reduced – from 10 working days to 5 days – and punctuality improved from 80% to 99%.

The management team’s awareness of how to handle problems has increased.

Management tasks by coordinators have been simplified, freeing up capacity for continuous improvement activities.

Measurement systems have been implemented to stabilise and monitor processes.

Benefits Obtained

01

The benefits achieved have had a positive influence on the team, triggering the continuous improvement process in operations. The individuals, who readily made themselves available and demonstrated a strong willingness to embrace change, welcomed the project with enthusiasm. People drive results, and only by changing behaviours can transformation succeed: this is the true difference between being lean and doing lean.

From Delivery to Demand

Following the activities carried out and the high level of engagement seen in the various projects, management independently launched several initiatives to improve processes, applying what they had learned from their experiences with the auxiell team.

SCAN

Lean Gap Analysis® in Demand

To analyse the current state of the processes, the auxiell-Marcolin Covering team carried out a Lean Gap Analysis®. In this initial phase, the team worked to ‘capture’ the current state of the sales process, involving the entire sales force and the complete product range.

Lean Gap Analysis®

An essential phase for measuring and analyzing current processes and defining the gaps between the current state and the desired one. In this first phase, we “photograph” the current state of the processes in terms of quantifying waste, identifying any problems and opportunities for improvement, as well as timing all phases. Having a clear vision of the process performance is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and designing, with a view to the future, the activities to be done – and which KPIs to measure – to make it more efficient.

Identified gaps

01

Lack of data for measuring process performance

The various phases of the sales process were not initially measured. Key metrics such as conversion rates, performance, and sales process lead times were unavailable.

02

Intuitive approach to customer management

The sales process relied on the skills of individual salespeople rather than standardised procedures. The wide geographical distribution of the team hindered the sharing of best practices.

03

High number of product variants

During the sales process, unexpected customisation requests were sometimes accepted, adding strain to both product development and production.

04

Long and unstable lead times from quotation request to submission of offer

Quotation requests had to go through the technical office, significantly extending order processing times. The queue of quotation requests was neither monitored nor quantified, making resource planning impossible.

05

The process of compiling commission copies was prone to errors

The information needed to prepare offers and orders was collected via a form in which customers could specify product modifications. However, unclear template fields and handwritten entries frequently led to errors, resulting in inaccurate offers or products that did not meet expectations.

PLAN

Lean RoadMap® in Demand

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Marcolin Covering team. The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

Phase in which the future state of the process analyzed in a multi-scenario perspective is designed. Once the most correct scenario from a technical-economic point of view has been chosen, we move on to planning the path to take to achieve it. The Lean RoadMap® shows the activities on which to focus and the timeframes in which to complete them.

The path forward

01

Future state map of the process

To make the sales process replicable and scalable.

02

Skill map: resource training plans

To standardise the knowledge of the sales network.

03

Implementation of process KPI measurement systems

To monitor the performance of the sales process based on objective data.

04

Creation of standards for gathering customer needs

To understand the intrinsic needs of the market and develop products or services that address real problems.

05

Demand-delivery connection: developing a system to connect sales to available production capacity

To structure the sales process so that the sales team knows when and how much to sell, ensuring greater stability in the production process.

Expected benefits

Increase in turnover

Increase in contribution margin

Acquisition of a deeper understanding of customer needs

Solidifying internal processes

Reduction in sales process lead time

DO

Lean Sales & Value Selling

Which lean activities and techniques enabled us to achieve our goal?

Future State Map

With the aim of speeding up and shortening the lead time between the moment of the offer and that of the order, we worked together with the Sales Manager and their team to create a new sales flow based on the customer’s purchasing process. We also analysed the best way to reorganise the phases with the corresponding 4M + E.In order to increase the level of service and support during the purchase, the network of Marcolin Covering’s authorised workshops in the territory was strengthened.

After creating the buyer personas – archetypes representing the company’s typical customers – we worked with the Marcolin Covering team to adapt the process standards to them and develop the Process Demand Book. This manual was essential for standardising the sales process and also facilitated the integration of new salespeople into the team, as well as the rapid training of new authorised workshops through its use.

Skill map

Thanks to the design of the future state map and the creation of standards, it was possible to define the necessary skills for the individuals working within the Demand process and create targeted training plans to make the resources both autonomous and efficient.

KPIs: Creation of monitoring dashboards

To enable the sales manager to control the sales process, several process KPIs were defined and are periodically monitored, such as number of customers acquired per sales team member, conversion rate, average revenue per order, lead time from quotation request to order, etc.

Poka Yoke

To prevent errors when filling out the commission copy forms, the template was simplified, standardised, and then digitised. The entire sales team was provided with a tablet to complete the forms and then send a PDF file to colleagues to prepare the quote.

Demand-delivery connection: developing a system to connect sales to available production capacity

To monitor the production capacity of the delivery process and enable the sales team to define when and how much to sell, a monitoring tool was implemented. This tool is accessible to both the sales and production teams, providing visibility into production planning for both teams.

Standards for identifying customer needs

To standardise the sales process, a set of questions has been defined for the sales team to understand emerging market needs and relay them to the R&D team so they can develop new products or services that meet those needs.

CHECK

Have we achieved our goals?

Optimising the sales process reduced lead time, improved service, and expanded the sales network. Standardisation and targeted training have made the team more autonomous, supporting customer growth. KPI monitoring and digitisation have increased efficiency, contributing to a 15% increase in turnover and a 16% increase in contribution margin in 2023. The improved alignment between sales and production optimised order management, while the structured identification of customer needs enhanced the company’s competitiveness.

The contribution margin increased by 16%.

Turnover increased by 15%.

Over 500 new customers were acquired in 2023.

The number of service points increased from 30 in 2019 to 210 in 2024.

From Demand to Development

The success in improving the Demand macro-process demonstrated the effectiveness of the strategies adopted and the team’s ability to improve performance, creating a positive model to follow. This experience provided clear evidence of optimisation potential and boosted the team’s confidence in their abilities. As a result, there was a clear intent to replicate and expand on these successes within the Development macro-process as well.

SCAN

Lean Gap Analysis® in Development

To analyse the current state of the processes, the auxiell-Marcolin Covering team carried out a Lean Gap Analysis®. In this initial phase, the team worked to ‘capture’ the current state of the development process for standard new products.

Lean Gap Analysis®

An essential phase for measuring and analyzing current processes and defining the gaps between the current state and the desired one. In this first phase, we “photograph” the current state of the processes in terms of quantifying waste, identifying any problems and opportunities for improvement, as well as timing all phases. Having a clear vision of the process performance is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and designing, with a view to the future, the activities to be done – and which KPIs to measure – to make it more efficient.

Identified gaps

01

Lengthy product development times

The time taken to develop and market a new product was significantly longer than market expectations, taking 166 days from concept to completion.

02

Project priorities and management methods were not clearly defined

Project importance and urgency were not clearly defined, and product development, customisation, and modification were all managed within a single value stream.

03

Large backlog of pending activities

Stakeholders frequently requested new projects and initiatives, but workload allocation across tasks and teams was unclear.

PLAN

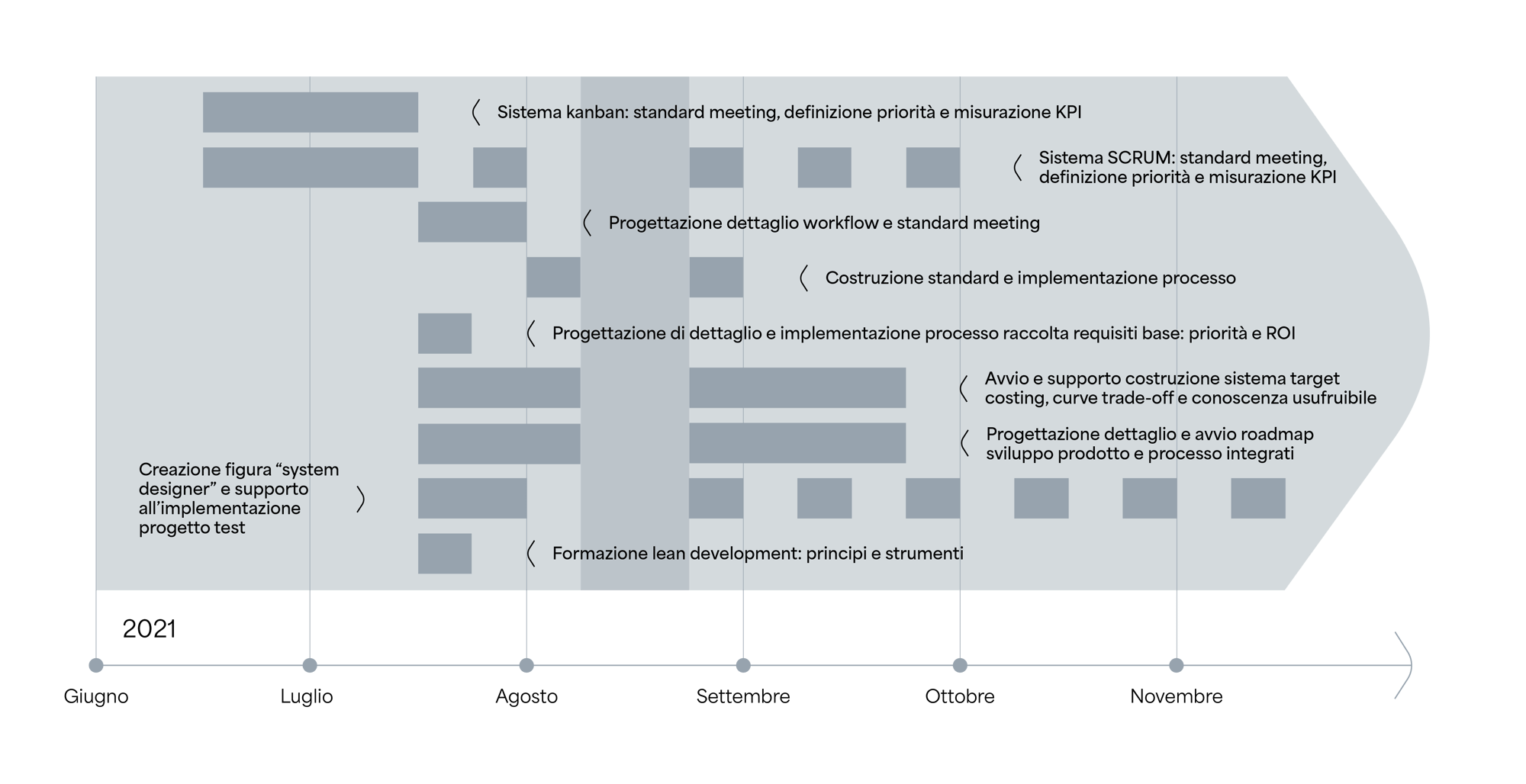

Lean RoadMap® in Development

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Marcolin team. The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

Phase in which the future state of the process analyzed in a multi-scenario perspective is designed. Once the most correct scenario from a technical-economic point of view has been chosen, we move on to planning the path to take to achieve it. The Lean RoadMap® shows the activities on which to focus and the timeframes in which to complete them.

The path forward

01

Subdivision of the various operational flows

We worked with the Marcolin Covering team to create different dedicated value streams based on the type of value generated: new product development, modification of existing products, and routine activities/one-off projects.

02

Definition of the characteristics of the above value streams

and the most suitable tools for managing the characteristics of the various requests.

03

Kanban implementation

For minor changes and product development, to quantify the backlog of activities and standardise the process throughput time (from project start to completion).

04

Framework scrum

For new product development, which allowed us to quantify and stabilise times within an uncertain environment.

05

Identification of the process owner of the development process

This coordinates the resources of these three value streams and balances them based on workload.

Expected benefits

Reduction of product development lead time

Increase in production capacity of the development team

DO

Design for Simplification

Which lean activities and techniques enabled us to achieve our goal?

Creation of value streams

We unpacked the processes carried out by the development department to create the three clusters and design the process to manage them as effectively and efficiently as possible, based on their characteristics from a 4M+E perspective. To enhance the level of service and support during the purchasing process, the network of Marcolin Covering authorised workshops in the area was strengthened.

Kanban

From the 4M+E analysis, it became clear that for the product modification and project management process, Kanban was the most suitable method to ensure the process flowed in the most effective way.

Framework scrum

From the 4M+E, it emerged that for the new product development process – due to its high complexity – Scrum is the most appropriate method to allow the process to flow as effectively as possible. During the daily sprint review, the team spends 15 minutes updating on the progress of the new product development processes, and stakeholders are updated monthly on the current status of the processes.

CHECK

Have we achieved our goals?

Optimising development processes improved operational efficiency through activity segmentation into dedicated clusters, adoption of Kanban for managing product changes and projects, and implementation of Scrum for new product development. These actions led to a 35% increase in task completion speed, a 60% reduction in the backlog, the introduction of eight new improvement practices in the team, and a decrease in the number of tasks closed with negative outcomes, ensuring greater effectiveness and responsiveness in development processes.

The task completion speed increased from 2.3 to 3.1 tasks per week.

The task backlog was reduced by at least 60%.

Eight new improvement and efficiency practices have been introduced as standards in the design team.

The number of tasks closed with negative outcomes has decreased significantly.

From Development to Deployment

The efficiency journey undertaken in Development has once again paved the way for implementing the same continuous improvement practices that led to excellent results in the first three macro-processes where they were initially applied. The goal remains to fine-tune processes, reduce waste, and increase productivity, ensuring better alignment between demand and development, thereby maximising the overall effectiveness of the organisation. This creates the need to move to the strategic level in order to align and coordinate the entire organisation with a lean approach, focusing on the Deployment macro-process.

SCAN

Lean Gap Analysis® in Deployment

To analyse the current state of the processes, the auxiell-Marcolin Covering team carried out a Lean Gap Analysis®. In this initial phase, the team worked to ‘capture’ the current state of the process of translating strategies into coordinated activities.

Lean Gap Analysis®

An essential phase for measuring and analyzing current processes and defining the gaps between the current state and the desired one. In this first phase, we “photograph” the current state of the processes in terms of quantifying waste, identifying any problems and opportunities for improvement, as well as timing all phases. Having a clear vision of the process performance is necessary to identify the most correct countermeasures aimed at removing the root cause of the problem and designing, with a view to the future, the activities to be done – and which KPIs to measure – to make it more efficient.

Identified gaps

01

Management lacked clarity on project priorities

Ongoing projects were not prioritised based on their strategic contribution to the company.

PLAN

Lean RoadMap® in Deployment

Once the gaps had been identified through the Lean Gap Analysis®, we moved on to the next phase, namely PLAN. Using the Lean RoadMap®, we defined the sequence of implementing the most suitable lean techniques to achieve the objectives agreed upon with the Marcolin Covering team. The Lean RoadMap® outlines the techniques and methods applied throughout the project.

Lean RoadMap®

Phase in which the future state of the process analyzed in a multi-scenario perspective is designed. Once the most correct scenario from a technical-economic point of view has been chosen, we move on to planning the path to take to achieve it. The Lean RoadMap® shows the activities on which to focus and the timeframes in which to complete them.

The path forward

01

Implementation of the A3-X

A tool aimed at defining projects relevant to the company strategy and correlating them to people, objectives, and key indicators.

Expected benefits

Greater alignment of projects with company strategy

DO

Hoshin Kanri

Which lean activities and techniques enabled us to achieve our goal?

A3-X

The company first defined its business strategies. Based on these strategies, all the projects at company level were defined, and through the correlation between strategy and project, the deselection phase was carried out – removing non-priority projects that did not align with the strategic objectives. Once the projects to focus on had been defined, the correlation with the team, objectives, and key performance indicators (e.g. process lead time, productivity, percentage of complete shipments, etc.) was established. These objectives were then classified according to the company’s financial results. Among all the projects to be set up, those crucial for achieving the strategy were defined, along with the objectives, the assigned team, and the related scheduled alignment meetings.

CHECK

Have we achieved our goals?

Strategic management optimisation was achieved through A3-X, a tool that enabled the selection of priority projects aligned with company objectives, the assignment of dedicated teams, and the definition of key performance indicators. This approach led to the standardisation of weekly sprint meetings of the Hoshin team and the completion of strategic training and alignment for all first-level employees, ensuring greater consistency and focus on company objectives.

Weekly sprint meetings of the Hoshin team became a company standard.

Strategic training and alignment were completed for all first-level employees.

From Deployment to future opportunities

The project in Deployment was the one that enabled all other projects in the other areas to move forward, now assessed as aligned with the company’s overall strategy.

Vuoi migliorare le performance della tua azienda?

I nostri esperti a disposizione per guidare la tua azienda alla trasformazione

Iscriviti alla nostra newsletter e ricevi contenuti esclusivi, consigli pratici e novità direttamente nella tua inbox!