Portfolio

ABS

Intro

How competitiveness was improved through a systemic view of processes and alignment with demand

Industry

Headquarters

Performance

achieved

Productivity

average daily

Performance

achieved

punctuality (LOTP)

stock reduction across the entire line

Do you want to improve your company's performance?

Company

history

1988

ABS was founded in 1988 through the merger of two highly skilled and long-established steelmakers: Officine Bertoli, founded in 1813, and Safau, whose origins date back to 1934. Since then, it has served as the steelmaking division of the Danieli Group.

Today

ABS specialises in the production of special long steels – highly specialised products for industries requiring high performance, advanced technical capabilities and mechanical applications. Its entire production uses the scrap-based cycle, which cuts emissions by 65% compared to the traditional blast furnace process. ABS supplies key industries that are constantly evolving, such as Automotive, Wind Power Generation, and Oil & Gas.

Employees (2024)

0Turnover (2024)

0EBITDA (2024)

0

The challenge faced by ABS

ABS turned to our team for support in developing a systemic understanding of its production processes. The objective was to drive business growth by establishing best-in-class supply and production processes aligned with the real needs of specific customers.

The starting point

The transformation of the first macro-process: Delivery

2022

– start of collaboration

with auxiell

The project continues

Together with ABS, we initially launched a project focused on the Delivery macro-process, which includes production, supply chain, and order management.

SCAN

Lean Gap Analysis® in Delivery

To assess the current state of processes, the auxiell-ABS team carried out a Lean Gap Analysis® of the entire Luna value stream – the process that starts with scrap and ends with bars in different finishes. The mapping covered everything from production in the steel mill to delivery of the finished product to the customer. Identified inefficiencies and improvement opportunities were found across the steelworks (from scrap melting to blumo creation), rolling mill, and finishing stages.

Substandard lead times to the customer

High levels of work-in-progress and a rigid production structure were negatively impacting overall lead times.

Variability in delivery performance

Deviations from planned schedules were affecting customers' perception of service levels.

WIP management between different process stages

The ‘batch and queue’ approach to managing finished flows led to stock accumulation at process discontinuities – particularly between the steel mill and the rolling mill, as well as in later stages. This was driven by misaligned production capacities across the various phases.

Phase efficiency

The focus on cost optimisation at each phase meant a lack of end-to-end process vision.

Decisions based on phase-specific indicators

The absence of process indicators limited the ability to make informed decisions about flow efficiency.

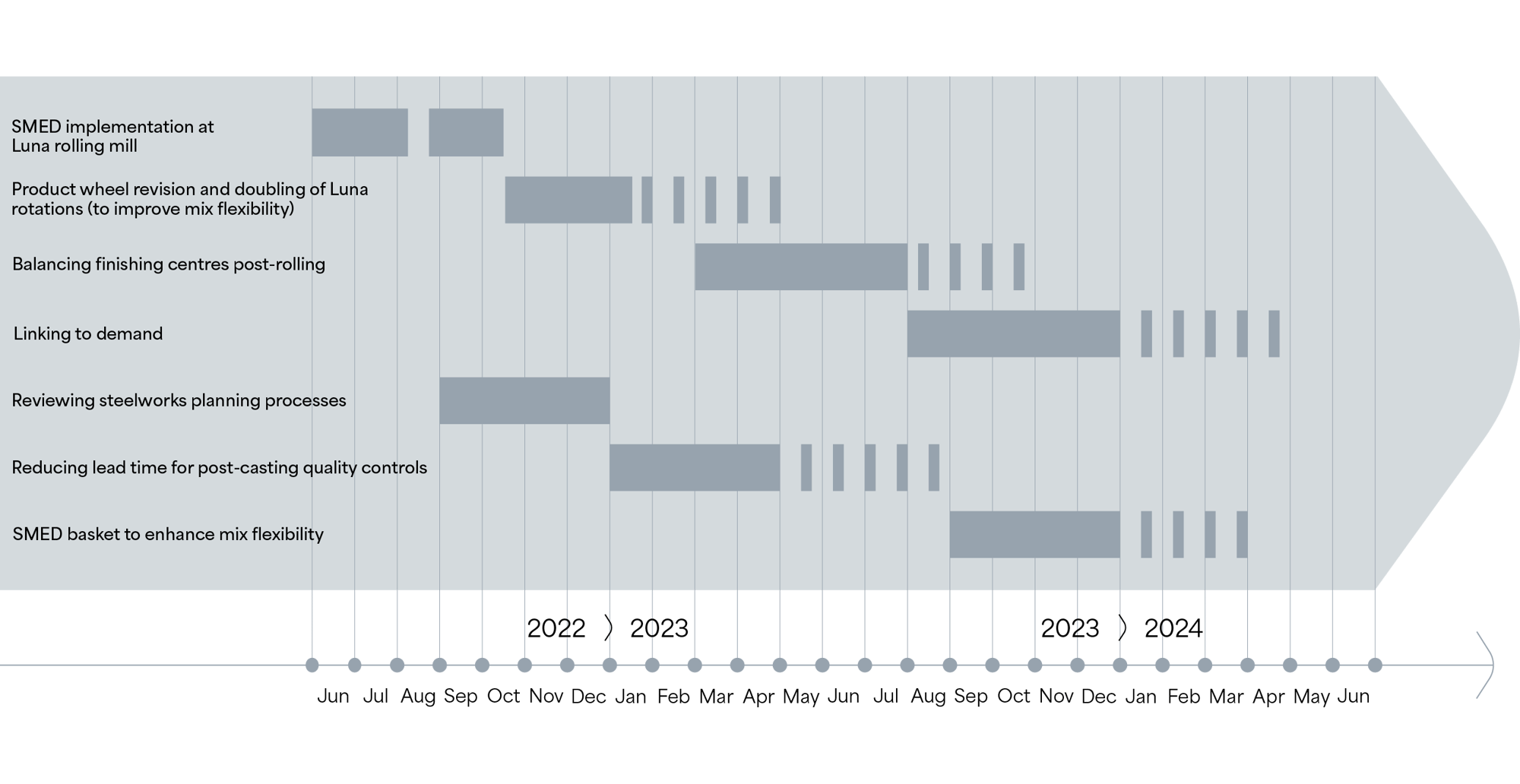

PLAN

Lean RoadMap® in Delivery

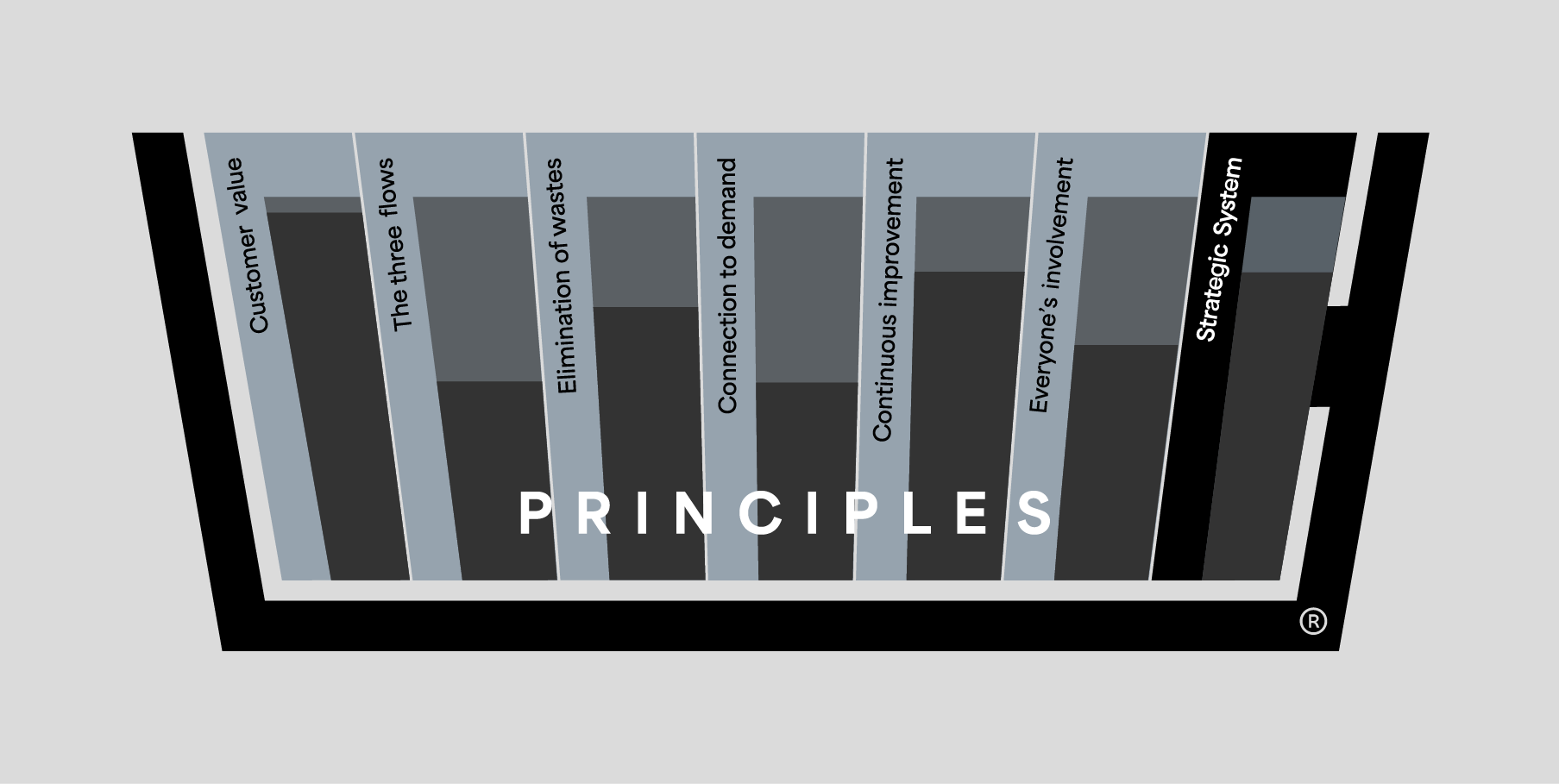

These insights formed the foundation of the next phase of the project: PLAN. Using the Lean RoadMap®, we defined the most suitable sequence of lean techniques to implement in order to meet the objectives agreed with the ABS team. The team specifically focused on:

Upgrading the rolling mill’s product wheel

To improve demand alignment and production flexibility.

Reorganising testing and laboratory operations using pull logic

To ensure that testing – carried out by those verifying process and quality parameters – and laboratory analyses – focused on product quality – were managed more efficiently and with shorter turnaround times.

Introducing a pull-based production management system

To shorten overall lead time and adjust the production capacity of each step to prevent bottlenecks and material buildup between stages.

Reviewing process KPIs

To make them more comprehensive, interconnected, and aligned with customer needs.

DO

Delivery Overall Transformation

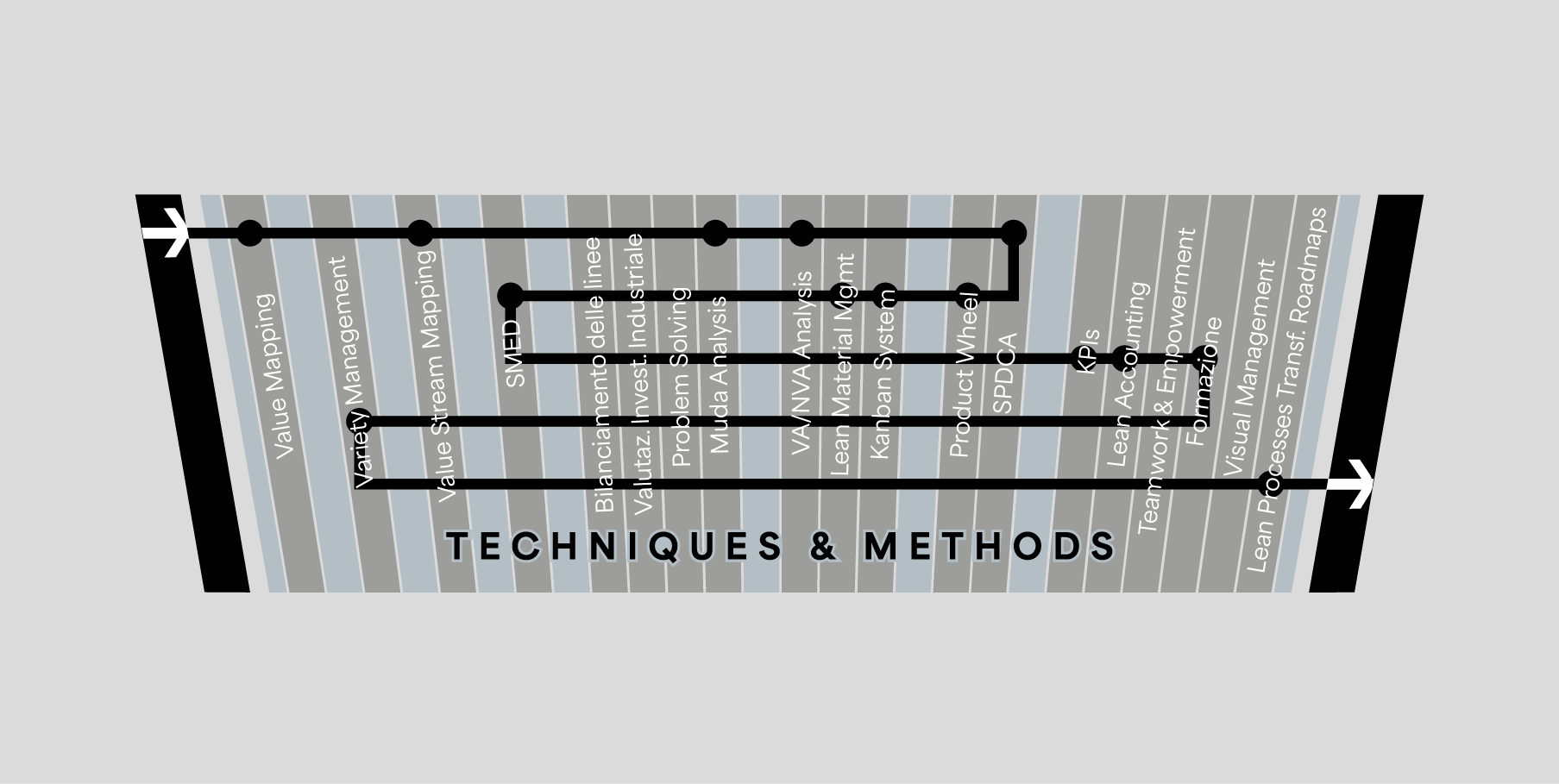

Which lean activities and techniques enabled us to achieve our goal?

Linking to demand and rolling mill's product wheel

By working jointly with production, quality control, the commercial team, and planners, the most effective actions were identified to fully understand customers' actual. With the support of edxiting, a workshop – the Steel Game – was organised dedicated to identifying customer needs and linking them to demand. Once the market response models were developed with ABS, customers were directly involved in the project, helping to define – in the greatest detail – the actions and tools needed to meet their requirements. In terms of production, the impact was a more levelled flow, enabled by stronger demand alignment through the introduction of kanban systems with selected customers. Thanks to visibility from the product wheel, some customers were able to adopt a 'capacity reservation' model, allowing them to book specific slots for their orders. This approach enabled testing and optimisation of the system, with potential benefits that can be scaled in the future.

Pull-oriented review of finishing flow

The entire production process was reviewed to identify and eliminate bottlenecks, ensuring uninterrupted flow during the finishing stages and avoiding delays or excess queues.

Extended problem solving: improved punctuality and reduced inventory

A cross-functional team – including planning, production, quality, and sales – applied structured problem-solving techniques to identify the root causes of flow disruptions and define a set of actions that would directly impact on punctuality and inventory levels. Two key aspects were addressed:

1. The planning logics and parameters in the steel mill, rolling mill, and finishing stages.

2. The integration of process steps to reduce inventory, shorten lead time, and improve productivity.

Review of process KPIs

Building on ABS’ existing indicators, a shift was made from phase-based KPIs to end-to-end process KPIs, focusing on what truly adds value for the customer. In particular, Lean on Time Production (LOTP) – measuring punctuality against the planned productions completion date – was revised, and two additional KPIs were introduced:

1. Shipped on Time (SOT): measures compliance with the promised shipment of the finished product, once the manufacturing process has been completed.

2. Lean on Time Delivery (LOTD): Monitors the on-time arrival of material at the customer’s site. This activity was carried out in close collaboration with the ABS team, which included representatives from various departments – from the commercial director to business development, as well as logistics and planning.

Pull-based management of laboratory analyses and testing

The testing phase was streamlined by making cut samples visible to the lab, introducing fixed times for laboratory technicians to collect samples, perform tests, and publish results within one day (down from four). Laboratory workflows were redefined, and a pull-based milk run system was implemented for specimen collection – made poka-yoke to reduce errors – which also reduced lead times for metallographic testing in the laboratory. Another improvement was made to the product quality certification process: the information flow was revised to align certificate prioritisation with the readiness of materials waiting for shipment.

Steel mill production scheduling with variable planning horizons

In order to reduce inventory between the steel mill and the rolling mill, as well as in the yards downstream of the rolling mill, the planning horizon was shortened. Initially, a 5-week time horizon was used. In the first phase, items were classified based on volume and consumption frequency using the ABC-RRS technique (an analytical method applied during the scan and plan stage). The proposed approach was to adopt differentiated planning horizons based on item rotation: 3 weeks for high-rotation items [runners] (consumed in at least 80% of the weeks analysed), 4 weeks for medium-rotation items [repeaters], and 5 weeks for low-rotation items [strangers] (consumed in less than 15% of the weeks in the period analysed). This classification was then entered into the management system to enable production planning in line with the appropriate lead times for each category.

CHECK

Have we achieved our goals?

Punctuality improved by 7% in LOTP, reaching the target set at the outset.

Stock levels of semi-finished and finished products were reduced by 17 %.

Several self-sustaining problem-solving initiatives were launched within the team level, which remains consistently engaged in independently improving processes.

Involving frontline staff from the sales, logistics, production, and management control teams enabled the organization of weekly project meetings, allowing prompt action in the event of deviations from targets.

The team has adopted a process-based mindset rather than focusing on the cost of individual phases. In some cases, this has meant opting for solutions that increase the cost of a single stage costs while reducing overall process costs.

These achievements positively impacted the team, whose members demonstrated remarkable openness to change and embraced the project with enthusiasm. People drive results, and only by changing behaviours can transformation succeed: this is the true difference between being lean and doing lean.

From the pilot store to the whole sales channel

The acquired method of pilot store redesign enabled management and the internal improvement team to gain awareness of the qualitative and quantitative benefits of Lean transformation. This led us to build an Aspiag standard for the analysis and redesign of all store processes and allowed us to start extending the improvements brought within the pilot store to all stores in the channel on a 3-year path.

Do you want to improve your company's performance?

Our experts are available to support your company through its transformation journey

Subscribe to our newsletter and receive exclusive content, practical tips, and updates delivered directly to your inbox!